Innovation doesn’t only happen at the beginning of an electronic device’s life cycle. Today’s devices are the product of innovations at all stages of a product’s existence—from creation to recycling. But opportunities and choices made during the development of a product often are the most important, and that is the focus of this review.

For years, the industry has fostered innovation and trends that during the past two decades systematically have reduced products’ impacts on the environment. Preliminary results from a recent study conducted by the Rochester Institute of Technology (RIT) and commissioned by Staples, available at www.cta.tech/cta/media/policyimages/rit-study.pdf, found that across consumer technology products, the number and type of products sold has—as you might expect—increased over the last two decades. The study also found that not only are fewer materials being used to make tech products, but also materials of concern, such as lead and mercury, are no longer part of the devices entering the market today. On a product-specific basis, our favorite tech products today use fewer materials than ever, making them smaller, lighter and usually easier to recycle.

These source-reduction achievements have been enabled by three important trends: technological shifts, convergence of multifunctional devices and the increased use of lightweight materials.

Using fewer and more-lightweight materials

The energy-efficient LG 4K UHD TV is a prime example of using fewer and more-lightweight materials—even while driving groundbreaking innovation. Honored (www.ces.tech/events-experiences/ innovation-awards-program/honorees.aspx) with the CES 2017 Innovations Award for Eco-Design and Sustainable Technologies, LG’s new 75-inch television is made up of an ultra-thin glass panel display—the thinnest on the market at just 2.67 millimeters—and weighs only 27 pounds. Innovative trends like this are resulting in not only bigger and better televisions but also in thinner, lighter displays that can be mounted more safely and easily recycled.

Demands for improved performance and a lower environmental footprint are clear. Consumers have long asked for products more conducive to the home environment, and their rapid adoption of TVs with bigger displays that provide better picture quality and that are slimmer and more environmentally friendly have made older models obsolete.

CRT TVs dramatically decrease

According to RIT’s preliminary results, the industry experienced peak volume of discarded, obsolete electronic devices in 2014 as an influx of older, heavier products left homes. Going forward, recyclers may see the number of incoming products increase even as the pounds they receive for recycling declines.

No one doubts that end-of-life cathode-ray tube (CRT) displays continue to make up a large percentage of the consumer electronics returned for recycling. However, the CE Recycling and Reuse Study (2016), available online at www.cta.tech/cta/media/policyimages/reuse-recycle-2016.pdf, the Consumer Technology Association’s (CTA’s) fourth U.S consumer survey on electronics recycling and the use of CRT screens in the home, revealed that in just three years, the number of American households with CRT televisions or computer monitors has declined from nearly half of all homes to just one-third.

Consumers have become and remain relatively well-educated about technology recycling. CTA surveys have found that overall awareness of technology recycling among consumers has remained consistently high since 2014, with nearly two-thirds (59 percent) of respondents knowing where they can recycle their consumer technology devices and nearly 9 in 10 (89 percent) agreeing it’s important to recycle old electronics. Approximately half of U.S. adults removed electronics from their households within the past year, and, among those who did, 4 out of 5 donated or recycled these devices. In fact, many of those surveyed said they found out about recycling options by word of mouth or through internet sources, and other said they gave used devices to family or friends for reuse rather than recycling, disposing of or selling them.

Innovations in packaging

Innovation in design is not limited to the product itself. Improvements in product packaging also have been integral in reducing the industry’s overall environmental impact. Manufacturers and retailers recognize that environmentally responsible packaging represents an effective opportunity to reduce waste by limiting the use of natural resources and by cutting emissions while also lowering costs.

That’s why many manufacturers and distributors take a deliberately innovative approach to their packaging design choices—decisions that not only get products to consumers undamaged (a critical source-reduction technique) but that also reduce size and weight, increase the amount of renewable content and enhance the recyclability and compostability of boxes, cushions, bags and other materials. Responsible consumers ensure much of this once-recycled material once again ends up in the recycling bin.

Producers assume responsibility

According to the Environmental Protection Agency’s (EPA’s) latest “Advancing Sustainable Materials Management Facts and Figures” report, available online at www.epa.gov/sites/production/files/2016-11/documents/2014_smm_tablesfigures_508.pdf, consumer electronics have the fastest growing recycling rate of any product category in the U.S. Through continued innovation and leadership from the consumer technology industry, CTA and its members are working to increase recycling and to make it easier for consumers to recycle their used electronics. Just last year, the eCycling Leadership Initiative (ELI), an industry effort spearheaded by CTA, announced that a record 700 million pounds of consumer electronics were recycled across the U.S. by manufacturers and retailers in 2015—40 million pounds more than in 2014 and more than double the amount recycled in 2010. (See https://cta.tech/news/press-releases/2016/April/a-recycling-record-700-million-pounds-of-CE-recycl.aspx for more information.)

The approximately $125 million spent by consumer technology companies on recycling in 2015 is more than any manufacturing industry has ever spent on recycling any product in the U.S. And more than 8,300 responsible recycling locations now are available to consumers throughout the United States. Never before has an industry taken this large a role in recycling its products so many years after selling them for use in people’s homes.

Secondary market growth: reuse

In the EPA’s nonhazardous materials and waste management hierarchy (www.epa.gov/smm/sustainable-materials-management-non-hazardous-materials-and-waste-management-hierarchy), reuse ranks above recycling in terms of preferred waste management strategies, and reuse in the consumer electronics industry is exploding. We now have a strong, growing secondary market for preowned mobile devices. For example, manufacturers like Apple and many mobile carriers give consumers a discount on new mobile devices when they bring back their old devices.

_fmt.png)

Companies such as NextWorth and ecoATM have even adapted or been created to support this secondary market for consumer tech. NextWorth collaborates with some of America’s largest retailers at 2,200 partner stores nationwide, allowing consumers to receive instant store credit for their used consumer tech devices. Since its inception in 2005, the company has served more than half a million customers and recycled millions of devices. ecoATM’s kiosks act as receptacles for more than 5,500 phones, tablets or MP3 players each, and employers will find a second life for the majority of the devices collected, while the remainder will be responsibly recycled at certified e-scrap reclamation facilities.

CES and sustainability

Every year, CTA hosts CES, the world’s gathering place for all who thrive on the business of consumer technologies. CES brings together technology companies, analysts, media and policymakers from around the world to witness the latest in innovation and to discuss the issues facing the industry today.

With the explosion of growth in the secondary market for mobile devices, the consumer electronics recycling industry is now showing that market demand can and does perform well on its own.

However, legacy products made with CRT technology and legacy state-level recycling regulations create challenges for all involved in this recycling policy experiment. To date, a patchwork of 25 different state electronics recycling mandates are sprinkled across the United States—most of them using extended producer responsibility (EPR) concepts with complicated compliance requirements—and shift more than $10 million annually away from collection and recycling and into a labyrinth of forms, fees and reports to file and be reviewed by state regulators.

Industry experts on a sustainability panel at CES 2017 touched on these issues. Mathy Stanislaus, then the assistant administrator of land and emergency management at the EPA, said, “The producer-responsibility policy has been a failed policy,” pointing to how the government’s attempts to mandate electronics recycling and other goals have fallen short. He did, however, express optimism that both sides will work together on future efforts.

Working together

EPA’s materials and waste management hierarchy puts the highest emphasis on source reduction as the best strategy for reducing waste. While this top-tier of the hierarchy has little visibility, the consumer technology industry is demonstrating how innovation and new technologies can reduce use of materials and waste and can sell more and better products at the same time. This is a model worth investigating further and replicating in other industries.

But industry cannot solve all environmental problems without others’ help. Government leaders and agencies, industry experts and consumers must work together to reduce the environmental impact of consumer tech devices. The industry has established a trend of using fewer materials in our products and, with the demand for tech products growing every year, manufacturers will follow through on that goal by delivering products that are as innovative in their sustainability as they are in their technology.

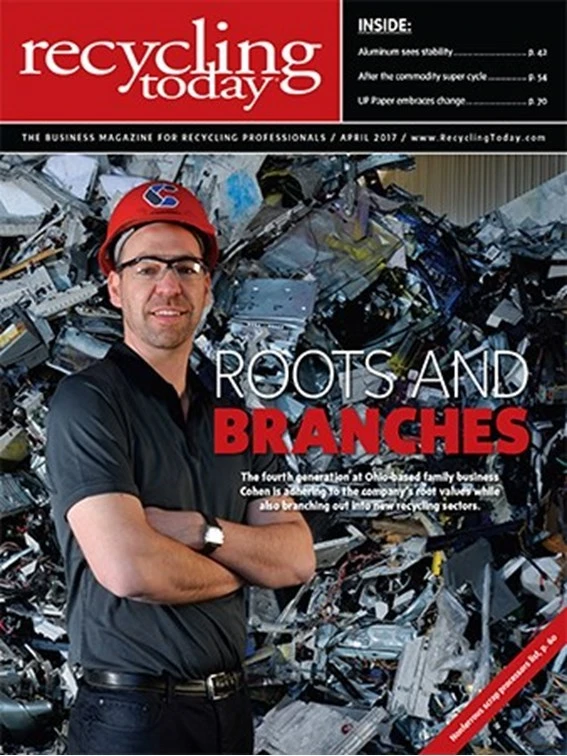

Explore the April 2017 Issue

Check out more from this issue and find your next story to read.

Latest from Recycling Today

- China to introduce steel export quotas

- Thyssenkrupp idles capacity in Europe

- Phoenix Technologies closes Ohio rPET facility

- EPA selects 2 governments in Pennsylvania to receive recycling, waste grants

- NWRA Florida Chapter announces 2025 Legislative Champion Awards

- Goldman Sachs Research: Copper prices to decline in 2026

- Tomra opens London RVM showroom

- Ball Corp. makes European investment