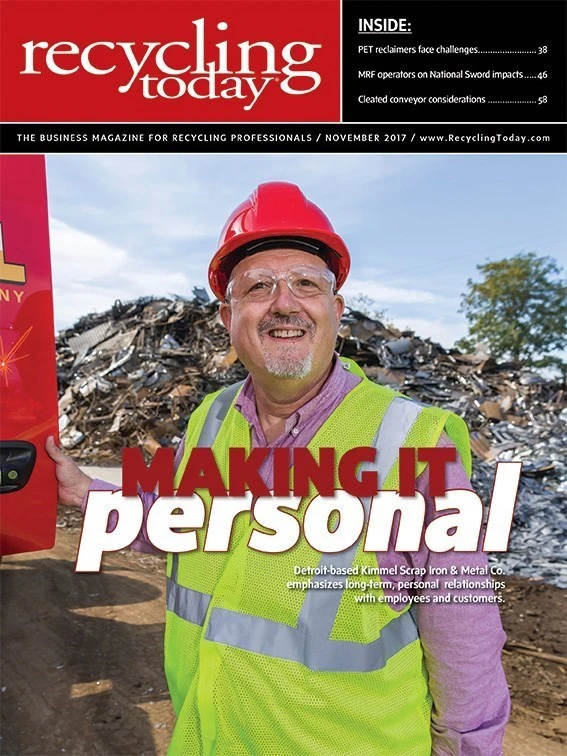

Owners of scrap metal companies can be tempted to either expand aggressively or sell out to a larger firm operating with a wider footprint. Robert Kimmel,

When describing what is distinctive about Kimmel Scrap Iron & Metal, Robert repeatedly mentions the long-time personal relationships with its customers as well as the personal touches the company’s management keeps in place with employees.

With that consistent philosophy staying intact, Kimmel Scrap Iron & Metal undertakes scrap buying and processing operations from a 20-acre site on the west side of Detroit, a city the family business has served since 1950.

Academic origins

Although Kimmel Scrap Iron & Metal has been operating in the Motor City for more than 65 years, the company’s roots trace back to a location near the University of Iowa campus in Iowa City, Iowa.

Kimmel Metal Co. was founded there in 1930 by Robert’s grandfather Ben Kimmel. “The scrap yard was founded near [the campus] and was involved with recycling many of its metals and steel,” Robert says.

“Ben Kimmel built up his company and was a direct shipper to many local steel mills in the area,” he adds.

While the company grew and prospered, Robert says it was clearly in an earlier stage technologically. “Rail cars were loaded by hand using wheelbarrows and shovels.”

The company’s Detroit era began in 1950, when Robert’s father, Morris “Morey” Kimmel, and his wife, Ruth Mason, moved there to start Kimmel Scrap Iron & Metal Co. Robert says, “Morris started with one truck, and his company evolved into what it is today: a leader in the recycling industry.”

Robert joined the family business full-time in 1978 (after a couple of years as a part-time truck driver) to continue what he considers to be the directive of his father and grandfather: “treating our customers as we would like to be treated and protecting our good name.”

Two other key managers at Kimmel Scrap Iron & Metal have arrived more recently. Vice President of Business Development T.J. Yarema joined the company in 2008 after having spent two decades working for General Motors and a hydraulics equipment maker.

Ken Schutt, the company’s chief operating officer (COO), joined Kimmel Scrap in 2013 after having served about a decade with another Midwestern scrap company. Prior to that, he was in the information technology field.

Schutt’s experience with his previous scrap industry employer included scale operations, truck dispatching, nonferrous scrap buying and plant management in Detroit and in nearby Toledo, Ohio.

While he was working in the Detroit area for his previous employer, “The opportunity to become COO for Kimmel Scrap Iron & Metal, a third-generation family-owned business, was a perfect opportunity and one that turned out to be the best for my career,” Schutt says.

Up close and personal

With its one processing site in Detroit, Kimmel Scrap has devoted its scrap purchasing and customer service to southeastern Michigan.

“Our main service area is the Greater Metro Detroit Area,” Schutt says. That includes Detroit and Wayne County (where Detroit is located) and eight nearby counties in southeastern Michigan. “However, we also service the rest of Michigan’s lower peninsula, along with service into Ohio and Indiana,” he adds.

As the company’s name implies, ferrous scrap lies at the heart of Kimmel Scrap Iron & Metal’s operations. “Processing consists of torching, with plans to move toward

As might be expected in the Motor City, buyers are “automotive suppliers—mostly tier 2, 3 and 4 suppliers, plus companies in the aerospace sector,” Schutt says.

The company does not have a retail or peddler scale. “We specialize in commercial and industrial scrap only,” says Robert, adding the firm has chosen to “steer clear of the peddler trade.”

Working solely with core industrial and commercial customers also has let Kimmel Scrap Iron & Metal concentrate on what it thinks it does best—maintaining long-term business relationships.

“We have customers we have had for 60 years,” Robert says. “You get to know their families; these are the personal relationships that got me involved and excited about the business in the late 1970s when I joined the company.”

It ties into Robert’s earlier comment about what he considers the directive of his father and grandfather of “treating our customers as we would like to be treated and protecting our good name.”

Robert’s father, Morey, died in 2014 after decades dedicated to the scrap industry, his

- We stress safety first and foremost.

- We say what we mean and mean what we say.

- We are ethical.

- We follow the road less traveled.

- We strive to be the best recycling/trucking company in the country.

- We exercise mutual respect.

- We have fun; we work and play hard, but we remember to enjoy what we do.

“These are the types of people we are and the types of people we employ,” Robert says. Several of those principles tie into how Kimmel Scrap interacts with its customers, but many—including the final one—relate to how the company manages and interacts with its employees.

A sense of fun

When asked what he thinks sets Kimmel Scrap Iron & Metal apart from some of its competitors, Robert does not hesitate before saying, “Our employees.” He adds, “I know this seems like an easy answer, but it is true. Our people are extremely dedicated, they love what they do, do it very well and take great pride in their work. As a result, they make Kimmel what it is.”

The company’s managers cite several ways Kimmel Scrap strives to let its employees know they are valued.

“We really work on safety, and showing a concern,” Robert says. “We will shut down our operation for one hour each month to help employees understand safety aspects.”

Another safety aspect involves running newer equipment. “We run new trucks,” says Robert. “Most of our trucks are newer; the oldest might be seven years old.”

Schutt adds, “Beyond trucks, the equipment within the yard also is cycled through to be fresh, reliable equipment. Also, employees can come to us with suggestions for safety or operations practices; that is where the best suggestions come from.”

The workplace climate Kimmel Scrap strives to maintain in part ties into Morey’s seventh principle of having fun. “My personal philosophy is ‘

That can mean a birthday celebration or a gift for an employee about to become a new father, or it might mean providing help to an employee going through a struggle. “So we share victories and losses,” Robert says. “It’s a tight-knit group that really fits well together.”

The philosophies that guide the company have kept it a vital part of Detroit’s scrap metal sector for more than 65 years, and Robert says he is optimistic the firm can continue to serve its customers long into the future.

“The relationship aspect of this business has not changed,” he states. “It used to

Regarding the future, Robert says, “I think this is our niche; this is what we do. Obviously, I’d like to upgrade our processing capabilities, but I don’t see a big change. I don’t see us trying to become a ‘megayard.’ I think we need to specialize in what we do well and keep doing that. The future looks very good for Kimmel Scrap Iron & Metal.”

Explore the November 2017 Issue

Check out more from this issue and find your next story to read.

Latest from Recycling Today

- Phoenix Technologies closes Ohio rPET facility

- EPA selects 2 governments in Pennsylvania to receive recycling, waste grants

- NWRA Florida Chapter announces 2025 Legislative Champion Awards

- Goldman Sachs Research: Copper prices to decline in 2026

- Tomra opens London RVM showroom

- Ball Corp. makes European investment

- Harbor Logistics adds business development executive

- Emerald Packaging replaces more than 1M pounds of virgin plastic