The mantra of "grow or die" follows around small business owners just as it does Fortune 500 corporate executives.

Like many other start-up business owners, David R. Powelson, CEO and founder of Tri-R Recycling, Denver, first had to survive some lean years before even being in a position to face the "grow or die" business phase.

| Tri-R Systems Corp. at a Glance |

|

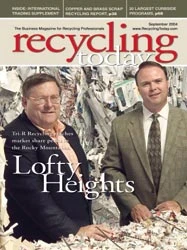

PRINCIPALS: David Powelson, CEO and founder (pictured at far left); Brad Heinrich, president of Tri-R Recycling (pictured, second from left); Mike Tingle, president of Tri-R Shredding (not pictured); Giles King, president of Secondary Fiber Inc. (not pictured) LOCATIONS: Office and main processing plant in Denver; Colorado Springs Recycling and Waste business unit in Colorado Springs; two buy-back centers in metropolitan Denver; more than 1,400 drop-off locations for recyclables NUMBER OF EMPLOYEES: 140 for Tri-R Systems Corp. business units combined PROCESSING EQUIPMENT: Includes two American Baler/Lindemann balers; Vecoplan LLC shredding plant; Machinex OCC disc screen; additional small balers, book de-binder, roll cutting guillotine and alligator shear; 40-truck collection fleet; four mobile shredding trucks SERVICES PROVIDED: Commercial recycling services; processing of residential recyclables; recycling programs for nonprofit organizations; secure document and product destruction services; material brokerage; solid waste and recycling collection (Colorado Springs); Internet-based information, shredding and recycling services |

But having made it through the survival stage, Powelson has assembled a leadership team at Tri-R that has helped turn the company into a growing regional powerhouse with subsidiaries and operations in several segments of the recycling, secure destruction and waste hauling industries.

A GROWING NEIGHBORHOOD. A visitor to Tri-R Recycling will see a company that has grown beyond its original land and building space to absorb adjacent properties in its neighborhood near downtown Denver.

Tri-R Recycling is, in fact, just one of five business units operating under the Tri-R Systems Corp. umbrella, along with Tri-R Shredding, DataGuard USA, Secondary Fiber Inc., and Colorado Springs Recycling and Waste.

The combined companies sort, bale and ship paper in the original plant, but also accept mixed residential recyclables, operate an outdoor sorting system, run a plant for confidential shredding, broker material shipments and supervise a variety of Internet-based companies with a national reach in the confidential shredding and recycling markets. Tri-R has recently purchased another building and its accompanying land to accommodate expansions in its shredding and municipal recycling segments.

Tri-R has steadily expanded the geographic range in which it operates, but its roots trace back to David Powelson’s desire to start a one-stop neighborhood recycling center.

Powelson, a native of New York City, has lived in Colorado since the early 1970s. His background includes a bachelor’s degree from the Wharton School of the University of Pennsylvania and an MBA degree from New York State’s university system.

After gaining work experience with another recycling company, Powelson started Tri-R in 1977. The company struggled at times in its early years before embarking on several strategies that helped fuel steady growth, including designing office building recycling programs and moving into document destruction services to cater to the same office clientele.

| High-Energy Future |

|

Currently, Tri-R Recycling of Denver faces some of its most difficult competition from low-cost landfills, according to company CEO David R. Powelson. Although landfill space may remain plentiful in Denver for some time to come, Powelson believes that it could be the energy markets, rather than the landfill or secondary commodity markets, that could ultimately change the way solid waste and recyclables are handled. If energy costs continue to trend upward, alternative fuel sources are bound to become more than just a curiosity. Improved sorting technology is already putting a greater volume of the municipal solid waste (MSW) stream in the hands of recyclers, he notes. But the implications of an energy market hungry for additional fuel "could be the biggest story the recycling industry has seen in some time," Powelson remarks. Systems in the works that allow recyclers to cleanly and efficiently operate or furnish plants that convert their residue into power that can be tied to the power grid could put them in a zero-waste position. Recyclers who can decide when it makes economic sense to ship grades for recycling or when to convert material to energy will have a helpful form of flexibility without the need for a landfill. "I think recyclers are poised to take advantage of a great shift," says Powelson. "It could be a real turning point for the industry." |

While confidential shredding has helped bolster Tri-R’s presence in commercial recycling, the company has not neglected its "neighborhood" recycling roots.

Individual residents’ drop offs of recyclables now make up just a small percentage of Tri-R’s overall business, but collection trucks (both Tri-R’s and those of other haulers) loaded with mixed recyclables feed an increasingly busy material recovery facility run by Tri-R. The company also manages some 1,400 collection points to bring in material from nonprofit organizations.

This curbside processing center, along with Tri-R’s acquisition of Colorado Springs Recycling and Waste, has made the company a major processor of curbside recyclables along Colorado’s front range.

That presence will grow by a huge leap in June of 2005, when Tri-R becomes the single-stream processor for residential material collected in the city and county of Denver. Tri-R is currently making processing equipment plans and purchases to handle the influx of residential curbside material.

The baled and shredded material processed by Tri-R’s different business units is ultimately brought to market by the company’s materials brokerage arm Secondary Fiber Inc.

This combination of business activities has resulted in a company with an impressive regional presence that operates a carefully monitored fleet of collection trucks; processing and sorting capacity—some inside and some outdoors—that has spread into a growing corporate campus complex; and an information, security and communications office infrastructure that connects Tri-R’s business units as well as plugs the company into its regional and national markets.

TEARING IT UP. When ranking the better business decisions made by his company, Powelson is quick to point to Tri-R’s early attention to the confidential shredding market.

"During a market collapse, we realized that we would lose money recycling files if we didn’t change our business model," says Powelson. "We decided to start charging customers to shred their files and to offer a certificate of destruction, pioneering this concept, as far as we know, in Colorado in the early 1980s."

The subsequent growth of this segment has resulted in Tri-R Shredding becoming its own business unit, as well as spinning off several Internet-based, shredding-related ideas into DataGuard USA, yet another business unit.

Tri-R Shredding combines the plant-based shredding operations that trace back to the 1980s along with the mobile- shredding-truck fleet acquired when Tri-R purchased a mobile-shredding company in 2000 co-owned by Mike Tingle.

Tingle is now president of both Tri-R Shredding and DataGuard USA, the business unit that has rolled out Web sites using their national reach to attract business from beyond the Denver area.

MARGIN CALL. The shredding operation has been one way to bring in material at a favorable cost, but by no means has Tri-R relied on this one source.

Brad Heinrich says the Denver area is similar to other metropolitan areas in terms of stiff competition for major scrap paper-generating accounts. Tri-R will remain on the hunt for these accounts, but is wary of serving them if the profitability of doing so disappears.

"Our niche is in serving small and medium-sized businesses," he remarks. "Some competitors want ‘X’ number of pounds on the dock or they are not interested. But we don’t tell any customers, ‘No.’ We’ll give them an option, possibly involving getting paid by providing shredding services or through a removal charge."

Making careful decisions on the account service side goes hand-in-hand with controlling operating costs and finding profitable end markets to create a business that can survive and thrive. "We are less about volume on the collection end and more about looking at the opportunities of each account," Heinrich remarks.

If, in theory, this strategy seems like one that could limit Tri-R’s growth, in practice it has instead resulted in steady and impressive growth.

Even with its practice of closely examining the profitability of accounts, Tri-R has grown to service hundreds of accounts throughout Colorado’s Front Range (where the Rocky Mountains meet the Great Plains), placing thousands of containers and operating a fleet of some three dozen collection trucks.

Additionally, material is brought to Tri-R’s Denver facility by individuals at the retail center (plus at buy-back centers in other Denver neighborhoods); is collected from fund-raising recyclable drop-off sites; and increasingly is tipped by hauling companies serving curbside programs and commercial accounts throughout the region.

Tri-R’s tonnage should continue to grow if plans to provide the city of Denver with single-stream processing service for curbside collectibles occurs in 2005 as planned. "I believe Denver is the last major U.S. city to not have single-stream recycling," says Powelson. "Effective 2005, that’s due to change."

While Tri-R has built its business, Powelson has been willing to learn from others as well as to pass along what he has learned. He has accepted leadership posts with the Paper Stock Industries Chapter of the Institute of Scrap Recycling Industries Inc., Washington, and also co-authored a 1997 book (along with his wife Melinda) called The Recycler’s Manual for Business, Government and the Environmental Community, billed as providing a "comprehensive guide [that] outlines necessary elements in designing and implementing a successful recycling program for almost any type of business or municipality."

DIFFERENCE MAKERS. Upholding profit margins is a necessity for any company that wishes to stay in business for very long. It is the practice of maintaining the margins that separates the long-term winners from the losers.

Similarly, customer service is recognized as a key management priority everywhere, but actually providing consistently high-quality customer service is challenging.

Powelson and Heinrich recognize that customer service is actually provided by the truck drivers, dispatchers and sales representatives that make up the 140-person staff employed by the various Tri-R Systems Corp. business units.

"Our people are empowered," says Heinrich. "Salespeople can solve a customer’s problem on the spot. Our salespeople don’t have to fax or e-mail something to corporate to get five signatures; they have the ability to make quick decisions that more often than not are the right decisions. More often you lose when you don’t make any decision. It’s been said that it’s not the big that eat the small, but the fast that eat the slow."

| Buying and Selling |

|

As befits the Tri-R business philosophy, the company is wary of accepting the additional material if it cannot be processed and marketed with an acceptable profit margin. Asked what the company’s biggest ongoing challenge is, Powelson replies, “To continue to find ways to maintain cost leadership.” Powelson, Heinrich, Tri-R Recycling Operations Manager Robb Espinoza, Secondary Fiber Inc.’s Giles King and a number of other key staff members consistently seek ways to procure material at a favorable cost, keep operations costs at a minimum and market grades of material that will bring a favorable price. Regarding operations, Powelson says the company enjoys a built-in competitive advantage with its central location and permission to operate outdoors. Additionally, Espinoza and other staff members vigilantly monitor operating costs and make adjustments to maintain low processing costs per ton. On the materials marketing side, Powelson says, “We consistently upgrade materials. This allows Tri-R to maximize the value of the products we ship.” But the procurement side remains the key, says Heinrich. “Our company is absolutely market-driven, not operationally driven,” he remarks. “The true opportunities are found by being creative on the buying end, allowing you to create profit.” Heinrich says creating recycling programs for some 3,000 accounts that can be vastly different from one another stems from asking customers what they hope to achieve and then tailoring a unique program. “We ask customers what they want to achieve, avoid and maintain, rather than presenting them with a ‘canned’ program. Our approach has helped us grow at a rate of 20 percent per year for a long period of time.” |

The collection truck drivers who service accounts are also seen as key personnel who work hard to follow instructions set up by the sales representative and the customer. "The sales representative can embed the values of the customer through every transaction, and the driver follows up by doing things just the way the customer wants."

Heinrich says the company "recognizes star performers" at the customer-service level and strives to retain its employees.

The end result has been that Tri-R has been able to "add people consistently without losing our core staff members," Heinrich says.

Tri-R’s attention to profit margins and customer service has helped it to thrive in a climate where the company competes not only with other recycling firms, but also with landfill costs that are among the lowest in the nation. Powelson calls Colorado’s landfills his company’s biggest competitor. "With four landfills in Denver alone, I’ve seen rates as low as $9 per ton," he comments.

Although the landfill situation is a challenge unlikely to go away any time soon, Powelson is confident that Tri-R’s opportunities outweigh its challenges.

He remains grateful for the one factor he credits for most often helping lift Tri-R above its competition: the company’s people.

In an industry that requires hard work hauling, sorting and otherwise handling what many people wrongly consider to be garbage, Tri-R has retained truck drivers and plant personnel for a decade or more and has kept its leadership team in place for just as long. (Heinrich has been with the company for two decades.)

"Our people simply outwork the competition," Powelson states. "We surround ourselves with highly motivated, dedicated people. We like to think that the harder we work, the luckier we get."

With the company’s decision to go about creating a single-stream processing plant in 2005 while continuing to serve its variety of commercial customers, Tri-R should have plenty of hard work ahead of it to improve its so-called luck on an even greater scale.

The author is editor of Recycling Today and can be contacted at btaylor@gie.net.

Explore the September 2004 Issue

Check out more from this issue and find your next story to read.

Latest from Recycling Today

- Returpack reports increased DRS activity in Sweden

- Trade groups align against European export restrictions

- Construction, auto sectors show mixed signals

- Politics in Turkey threaten recycled steel outlet

- Toppoint Holdings expands chassis fleet

- Lego creates miniature tire recycling market

- Lux Research webinar examines chemical recycling timetables

- Plastics producer tracks pulse of wire recycling market