Bodner Metal & Iron has been a part of the Houston economy since 1948, covering a span when Houston grew from a regional oil town into one of America’s

major cities.

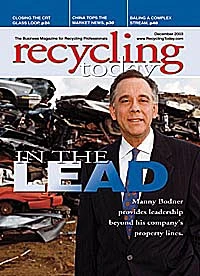

The company was founded by Eugene (Gene) Bodner in the post-World War II era, with Eugene being joined by his son Emanuel (Manny) in 1969. Gene now serves as a senior advisor to the company while Manny serves as president and his sister Karen Bodner is the corporate secretary.

The Bodner family members have shepherded the company through what used to be a set of boom-and-bust cycles in Houston, all the while finding additional time to act in leadership roles in their state and in the scrap recycling industry.

HOUSTON RISING. Scrap recyclers are all too familiar with the cyclical nature of commodities, and at one time so were all Houstonians. "In the 1980s, when Texas was so dependent upon oil, if the oil industry would sneeze, the scrap industry here would catch the flu," says Manny.

|

|

In those previous decades, Manny notes that cotton, cattle and oil—all cyclical commodities—drove the Houston economy. Although those industries are still very much in evidence in Texas, the Houston economy has diversified well beyond them.

"We’ve seen such a diversification and there is a lot of building and construction at all times," says Manny. "The Houston office towers, the office park construction in and around Houston, that’s an advantage for those of us in the scrap business here. It seems like we’re always building. As bad as markets might be elsewhere, Houston just doesn’t get that bad. And by the same token, when markets swing way up, Houston is already there to some extent."

The booming office, service, technology and commercial sectors of the Houston economy have changed the nature of how Bodner Metal & Iron operates compared to earlier decades. "We’ve certainly, as a company, shifted dependence away from relying on just the oil-related segments of the industry," says Manny.

From a 10-acre location in north central Houston, Bodner Metal & Iron, serves a variety of industrial and commercial accounts, as well as taking in scale traffic carrying both ferrous and nonferrous metals. (The company will also "market selected grades of paper and plastic," according to Manny.)

The company’s cranes, loaders and forklifts handle incoming material and direct it either for direct outbound shipment or, more commonly, for further processing in the form of shearing, torching and flattening on the ferrous side, and for shearing or baling for the nonferrous grades.

The company’s indoor nonferrous facility handles a variety of industrial and contractor (construction, demolition and remodeling) scrap, and also handles aluminum used beverage containers (UBCs). "We promote the UBC collection as a public service for our community," notes Manny.

Portions of the company’s across-the-scale traffic rise and fall with commodity prices, and Manny says the number of industrial accounts in Houston has been affected by the manufacturing slump just as it has in other parts of the U.S. "The base of materials that is generated as industrial scrap is not as large as it once was," says Manny. "We’ve seen a lot of machine shops, for example, move offshore, and we’ve seen the manufacturing sector contracting."

The saving grace for Bodner and other Houston processors, however, has been the booming building market in Houston. "We’re seeing more of what I call a commercial scrap," says Manny. "Some of it is demolition scrap and some of it is what I call maintenance scrap. When plants or refineries in the area do a major repair or expansion, or if they are changing out their HVAC vents or pipes, these types of jobs yield that maintenance scrap."

Manny acknowledges that Bodner Metal & Iron is by no means the largest scrap processing firm operating in Houston, but he says he and the company’s other managers pay attention to stay attuned to the right opportunities and to forge relationships with key suppliers. For instance, Manny notes that the company over the past decade or so the company has been emphasizing acquiring post-consumer scrap such as automobiles, white goods and agricultural scrap.

"You try to position yourself to take advantage of opportunities," he remarks. "We work with construction and demolition contractors, without question. Our philosophy is built on relationships. I believe the basis of our business on both the buying and selling ends are very definitely built on relationships.

SERVICE CALLING. Many scrap recyclers, Manny Bodner among them, believe that scrap recyclers are in the service industry as much as they are in an industrial products sector.

Manny has committed not only his company to the notion of service, but has devoted himself to serving regional and state civic causes, as well as recycling industry-specific causes.

Within the industry, Manny has long been active with the Institute of Scrap Recycling Industries Inc. (ISRI), particularly with its Gulf Coast Chapter. "I think that firms engaged in recycling should be members of their trade and professional association," says Manny of ISRI involvement. "In my mind, it’s more than a trade association, it’s a trade and professional association. What I enjoy is that in the association, and in the chapter, we tend to challenge each other to think beyond ourselves. I find that very exciting. There is tremendous talent within the chapters and within the national organization. Our industry needs the expertise to evolve into the next phase."

Manny currently serves as Gulf Coast Chapter first vice president, editor of the Chapter’s newsletter, helps plan the annual convention (see sidebar), and has served in the Chapter officer roles in the past, including president. He is slated to again serve in the other Chapter officer ranks over the next several years.

"I enjoy my work serving the industry through ISRI," says Manny. He notes that the contacts made throughout the years have been both gratifying and valuable, particularly as some scrap companies have entered the national accounts business.

Some of those companies know Manny through his ISRI involvement and have contacted him regarding business opportunities servicing customers in the Houston region. "We provide a service whereby material is brought into our facility, we unload it, place it in inventory and consolidate until there is a suitable volume to be shipped," explains Manny. "I am honored when a colleague from another part of the country asks me to participate in servicing their clientele. We’re very honored to do that for a number of other companies."

In addition to his Gulf Coast Chapter duties, Manny has been involved with ISRI’s Design for Recycling Committee, which works with product manufacturers, designers and their trade associations to urge them to consider the recyclability of the products they make. "I think the impact on our industry can be dynamic," says Manny. "I think we’re finding great support and firms and manufacturers already involved in Design for Recycling."

Manny has also served on community and state volunteer committees and panels unrelated to recycling. He played a key part in a regional clean-up and beautification effort in the early 1990s to prepare for an international economic summit (see sidebar on page 66). Manny has also served on a Texas Governor’s committee on disabled persons in the 1980s; served as a board member of the Texas Rehabilitation Commission from 1985 to 1991; and in 1994 he began his involvement with a state board that licenses and regulates physician assistants.

| BRINGING THE INDUSTRY TOGETHER |

|

Manny Bodner is one of several people who has worked in the past several years to make the ISRI Gulf Coast Summer Convention a gathering that brings recyclers and suppliers from throughout the Gulf Coast region and well beyond together in one place. Bodner has been among those planning the 2004 Gulf Coast summer event, which will take place June 16-19 in New Orleans. The four-day event will feature several sessions covering virtually every secondary commodity traded by ISRI members: ferrous scrap, aluminum, copper, paper, precious metals, lead, zinc, paper, electronic scrap and tires. Other topics covered in educational sessions will include international trade issues; ISRI’s new Scrap3 certification process and its Design for Recycling program; a motivational talk from LaDonna Gatlin, sister to country music’s Gatlin Brothers; and a panel of scrap industry patriarchs (Morley Denbo of Tennessee Valley Recycling; Seymour Padnos of Louis Padnos Iron & Metal; and Stanley Rabin of Commercial Metals Co.), who will discuss the colorful history of scrap metal in America. Also part of this year’s event will be the annual golf tournament, an exhibit hall with displays from industry suppliers, and several lunch, dinner and cocktail reception networking events. Those seeking more information on the June event can contact Manny at scrap@bmicorp.com. |

Manny served on several subcommittees to the board, chairing the long-range planning and finance committee, before eventually serving as chairman of the overall board. "I was one of the first non-medical professional member so elected as the chairman of a major board of medicine," notes Manny. "I have always been interested in state government," says Manny. "I feel as though I am making a contribution."

CONTINUOUS IMPROVEMENT. After more than three decades in the scrap industry, Manny has observed several changes and acted to create some changes of his own.

Processors who wish to stay profitable should be keeping an eye on operational efficiency, notes Manny. "I think the trend started 20 or 25 years ago—you don’t just set up a yard or a plant and then you’re finished," he comments. "You must continue to improve and continue to improve. Compared to 25 years ago, I really think that there is a change. If a yard is going to be successful, then the operations should be not only formally reviewed, but just whenever you are in your facility, you need to look at how you’re producing."

The era of the large shredder has dawned since Manny became involved in the scrap industry, and he is continuing to compete in that environment. "We’re able to serve clients that other companies are not able to serve; we can still serve new customers," Manny remarks. "Regardless of what equipment you have, you must adapt, and I feel confident we have. We’re boosting our tonnage, we’re growing and we continue to grow."

While keeping one eye on operations, the buying and selling aspects may be what Manny enjoys most. "I find I enjoy trading most, because, as we develop our trading side, that is developing our marketing side," he says. "By being active in trading and marketing, we can develop new customers and to grow our business."

Relationships remain a key reason Manny enjoys his work as well. "I enjoy my work in the industry through ISRI, and I enjoy the relationship I have with my family. My father Eugene is chairman with us and he is very involved. He’s our founder. My sister Karen serves as Corporate Secretary. Karen is our representative to generating customers. She has a wonderful disposition and is able to discuss a variety of subjects with our clients."

Each of the Bodners has a defined role, and they function well as a team. "I get to work with both of them on a daily basis," notes Manny.

The image the company projects has been a key to its ongoing success, he also notes. "People enjoy doing business with us, quite frankly. They know we’re going to be honest with them and tell them what we can do and what we can’t do. We’re not perfect; nobody is."

Integrity is a quality that Manny says helps set successful operators apart. "I think credibility, reliability and integrity are keys. You have to say what you’re going to do and you have to do what you’re going to say. And explain when things when go wrong. Accountability is another important word."

There is no crystal ball Manny can look into to determine the future, but he feels that a carefully managed company should continue to be presented with opportunities in the Houston area. "I see continued growth in the Houston area in the metals industry," says Manny. "That is not to say that some companies won’t move out and move in. But I continue to see Houston in a very positive light. The market is as it is; we work with that market."

| RISING TO THE SUMMIT |

|

Manny Bodner, president of Houston’s Bodner Metal & Iron, has been quick to volunteer for civic causes, and saw an ideal opportunity to do so when a call went out to beautify the Space City. The call for a clean up was in preparation for the 1990 Economic Summit of Industrial Nations, which took place at Houston’s Rice University and was hosted by the U.S. while Houstonian George H.W. Bush was in the White House. "At that time there was a great call for companies to come to the assistance and clean up our city, to make it more presentable," recalls Manny. "There was a lot of effort and a lot of things we did," he says of the Houston business community and his company in particular. Manny recalls that one of the solid waste companies provided an abundance of containers and trucks to assist the clean up, "and we participated and provided containers also," says Manny. "Speaking as a native Houstonian, it felt like it was a small town again, the way people came together. As a result, they had the Economic Summit, leaders from throughout the world met at Rice University, and we were able to participate in a small way." Although collecting materials other than metal was something new for the company, volunteering for the Summit provided a toe in the water that has allowed Bodner Metal & Iron to venture into paper, plastics and solid waste as a way of providing additional services to customers. "From that time on, we’ve begun to provide some of that service to our industrial and commercial accounts as needed. It was out of our scope, but it’s certainly something we could do." . |

No matter what the market brings, Manny says Bodner Metal & Iron is preparing to work with what comes its way. "We’re always going to evolve. We’re always going to try to be in a position to service our markets in the best of our ability, and to grow and to respond as best we can."

The author is editor of Recycling Today and can be contacted via e-mail at btaylor@RecyclingToday.com.

Get curated news on YOUR industry.

Enter your email to receive our newsletters.

Explore the December 2003 Issue

Check out more from this issue and find your next story to read.

Latest from Recycling Today

- LumiCup offers single-use plastic alternative

- European project yields recycled-content ABS

- ICM to host colocated events in Shanghai

- Astera runs into NIMBY concerns in Colorado

- ReMA opposes European efforts seeking export restrictions for recyclables

- Fresh Perspective: Raj Bagaria

- Saica announces plans for second US site

- Update: Novelis produces first aluminum coil made fully from recycled end-of-life automotive scrap