Whether you’re buying a machine for the first time, upgrading incumbent technology or expanding an existing facility, procuring an industrial shredder is a time-consuming and potentially complex process. Mark Williams, an experienced shredding specialist at UNTHA America, offers practical advice to help buyers make the best value decisions.

1. Define your input material

Be specific about your material composition. A key question to answer is: What is the largest bulky item I need to shred? This helps define the cutting chamber size that will successfully accept the material. Width, length and depth dimensions are required.

If input material is likely to vary, that is OK—many shredders now are designed for application flexibility.

2. Understand output requirements

Work back from the furthest point in the supply chain. Whether you are producing a commodity and need to consider end-user requirements or simply need to ensure the compliant size reduction and disposal of materials, the final output criteria are important.

Think about particle size and the need—or not—for fraction homogeneity. Also consider throughput requirements, as this will determine the motor drive power (kW) required.

3. Consider ancillary equipment

How will input materials be fed into the shredder? Shredders can be fed manually, or with a grab, front-end loader, conveyor, forklift or bin-lift, for example. When it comes to output material, mechanical or pneumatic extraction typically is required unless relying on gravity discharge into a suitable container.

Additional upstream and downstream equipment also may be needed, depending on the complexity of the product and output requirements.

If you are uncertain about the right design for your shredding solution, ask. This exploratory discussion will ensure optimal performance, accurate budgeting and adequate space planning.

4. Do you have sufficient power?

What power is required to run the machine and do you have enough supply? This often is overlooked.

5. Define timescales

It is important not to rush decisions, but sometimes wider timescales dictate the schedule. Define the ideal commissioning date—inclusive of acceptance testing and operator training—and work back.

6. Know your numbers

Decide on a budget, but do not simply consider the initial shredder cost. On-going operational efficiencies, energy consumption, uptime, ease of maintenance and parts longevity will all affect long-term cost efficiencies and profitability.

If in doubt, ask potential shredder providers to help build a business case, including the likely payback period and potential revenue yield from output material.

7. Be clear on the project ‘driver.‘

Be open and honest with shortlisted suppliers about what you want to achieve. There is little point investing in a shredder to tick an environmental box, for example, if the technology is diesel-hungry—especially when cleaner, greener, electric-driven solutions are available. It now is even possible to power heavy-duty shredders using solar energy!

8. Agree on the decision-making process

At the earliest feasible stage, define who will be involved in the procurement process, especially the final buying decision. Consult the right people at the right time so you do not delay the outcome.

9. Research, research, research

Conduct online research, attend expos and read trusted magazines. Also, think about who you know—other equipment suppliers, peers and industry organizations could prove helpful.

10. Do not be afraid of detail

Ask detailed and specific questions relevant to your business model and material-handling scenario to understand a shredder’s true performance capabilities and the supplier’s ability to meet your needs.

For example, confidential waste shredders benefit from being slow-running, as they can shred classified material to an agreed specification without destroying the fiber and recycle quality. You also need peace of mind that you will achieve DIN compliance without fail.

If your goal is alternative fuel production, output precision matters, as does the whole-life running cost of the machine. Both will affect the future profitability of an RDF or SRF manufacturing plant.

11. Increase resistance to foreign objects

Where possible/relevant, ensure the shredder has foreign object protection. The contents of waste streams can never be guaranteed however rigorous any pre-sorting processes. Built-in protection mechanisms can auto-stop a machine if a foreign object is detected, preventing shredder damage, minimizing downtime, ensuring the longevity of parts and upholding output quality.

12. Seek safety as standard

Operator safety is non-negotiable, so look for design features that ensure safe and ergonomic working conditions. Safety is paramount, from low noise levels to slow speeds that minimize dust and safe employee conditions.

13. Prioritize preventive maintenance

The ease, speed and cost of maintenance are incredibly important, as this will impact future profitability, especially in high-throughput applications such as waste processing for alternate fuel production. Simple maintenance procedures and quick cutter change times ensure maximum uptime and shift efficiency, which could equate to hundreds of thousands of dollars saved in 12 months alone.

14. Empower your team

Ensure comprehensive training will be provided, even if the shredder is easy to use and remote diagnostics are offered. Operatives must understand how to use the shredder, safely, while optimizing ongoing operational efficiencies.

15. Request references

After shortlisting preferred shredders, speak to other customers or visit sites where the technology already is installed. Watch how the equipment performs, ask questions of the plant owner/operators and assess other factors such as noise levels. Certain suppliers may even offer a trial, allowing you to truly test the machine with your materials.

16. Is your customer experience being prioritized?

Where possible, consider the shredding supplier as a partner and evaluate the business on their heritage and experience, commitment to continued support and long-term desire to collaborate with you.

17. Plan for the future

Organizations cannot stand still, especially in an ever-changing industry, so shredders must be flexible without being over-specified. It will need to adapt alongside your business if your throughput or fraction size requirements change. Otherwise, if the technology needs to be replaced, the investment could end up being very costly.

For more information or to discuss this advice in further detail, please contact UNTHA America at 603-601-2304 or info@untha-america.com.

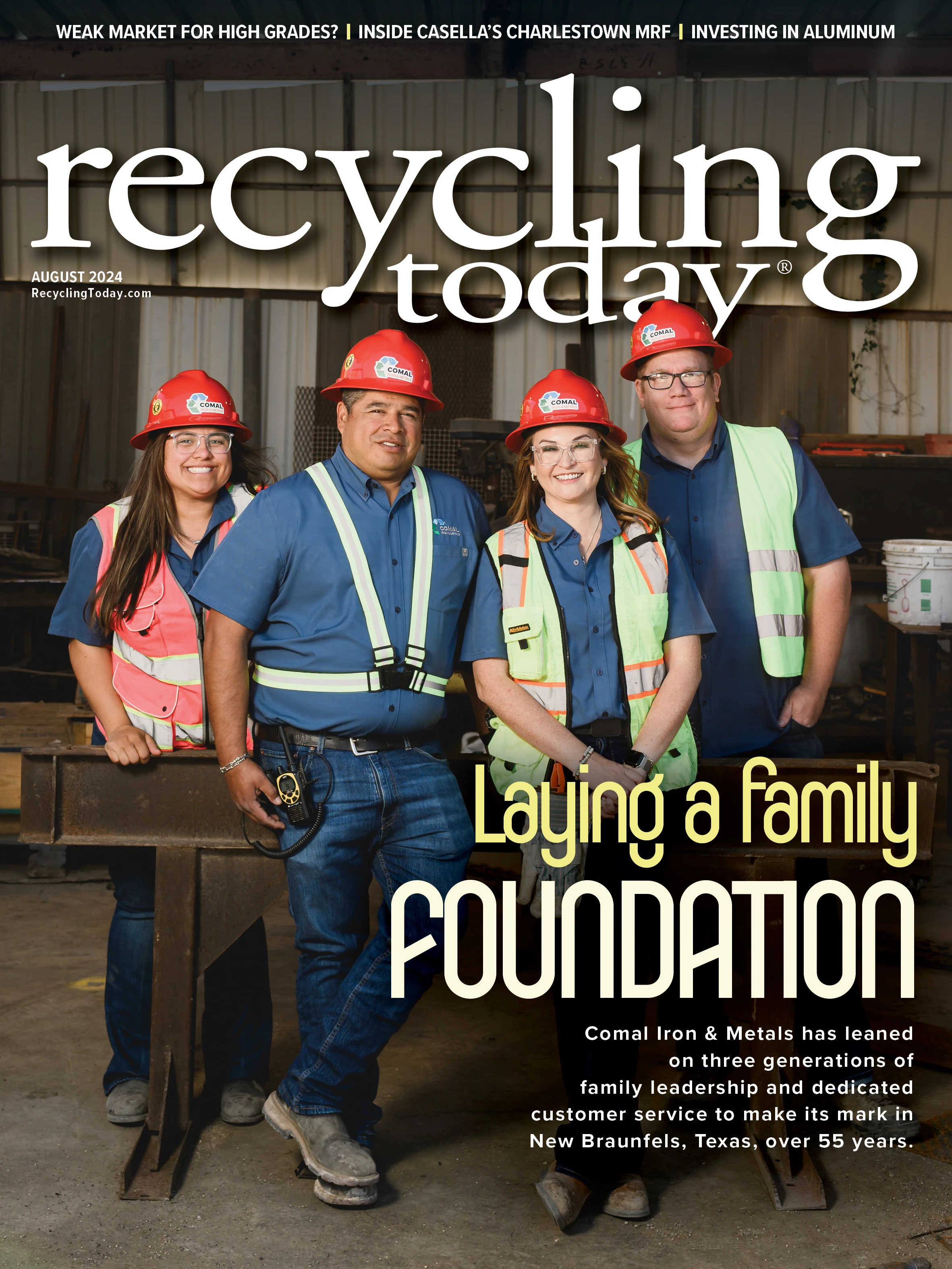

Explore the August 2024 Issue

Check out more from this issue and find your next story to read.