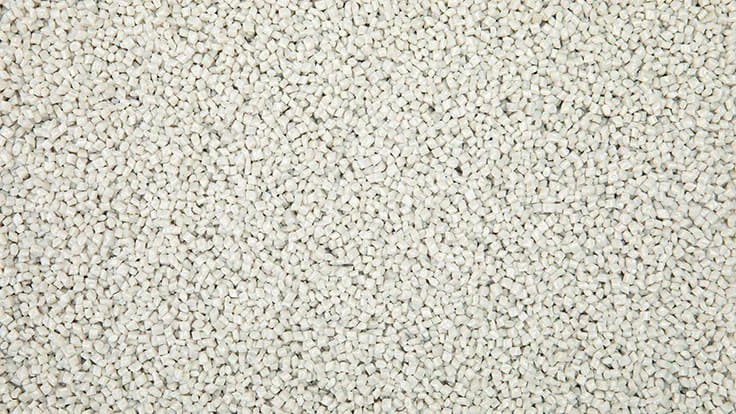

Photo courtesy of Evergreen

Plastics recycling company Evergreen is undergoing an expansion at its plant in Clyde, Ohio, that will double its food-grade recycled polyethylene terephthalate (PET) processing capacity from roughly 40 million pounds annually to 80 million pounds annually, says Greg Johnson, Evergreen corporate vice president.

Late last year, the company added six robots on its sorting line that were supplied by Amp Robotics of Denver, Colorado. The robotic sorters are after the optical sorters on the whole bottle sorting line, and Johnson says they have helped to improve the consistency and quality of the material. He adds that the robots are negatively sorting the PET bottles, removing colored bottles or those with certain labels and non-PET bottles that may have gotten past the optical sorters. He says the robots provide the “final polish” and “are not a replacement for optical sorters.”

Johnson says Evergreen also is upgrading four of the six optical flake sorters on its wash line with equipment from Germany-based Tomra Sorting Recycling.

To accommodate a third pelletizing line, Evergreen is expanding the size of its 240,000-square-foot facility by 54,000 square feet. The pelletizing line will be supplied by Vienna-based Starlinger. Johnson says Evergreen’s other two pelletizing lines were supplied by Erema, an Austrian company with a U.S. subsidiary in Ipswich, Massachusetts. They include a Vacurema Advanced extrusion system installed in 2004 and a Vacurema Prime extrusion system it installed in 2011.

Evergreen also will install two solid-state polycondensation (SSP) reactors from Starlinger on two of its pelletizing lines. The SSP reactors decontaminate the flakes and increase the intrinsic viscosity of the rPET pellets the company produces, according to Starlinger.

Groundbreaking on the expansion will be in May, Johnson says, with the new pelletizing line expected to come online in mid-2022. “The building will be done in the fourth quarter,” he says. “We’ll be starting the equipment installation after that, with mid-2022 start-up.”

Given the issues associated with ocean shipping currently and that the equipment will be coming from Europe, Johnson says the company’s timeline accounts for potential delays. “Right now, everything looks very promising.”

When the expansion is complete, Johnson says all the company’s pelletizing lines will have a similar setup that will allow Evergreen to produce clear, food-grade pellets for the bottle and sheet markets.

“Demand for rPET is extremely high,” he says. “We want to grow with demand.”

Polychem rebrands, expands services

Evergreen’s parent company, Polychem LLC of Mentor, Ohio, also has announced a new name and a new business strategy. The company, which provides end-of-line packaging solutions, has changed its name to Greenbridge, which it says better reflects its portfolio of products and services, many of which are made of 100 percent recycled material, and its new strategy to help major companies meet their circular economy goals, reduce their reliance on landfills and address their environmental and social governance (ESG) goals.

In a news release about the changes, Greenbridge CEO Omar Abuaita says America’s renewed emphasis on the environment has struck a chord with consumers who want more accountability from the companies they support. Recognizing an opportunity to bridge the gap from current operations to a true circular economy model inspired the company to lean into its strengths in recycling, reuse and sustainable business practices to bring comprehensive sustainability solutions to customers in packaging, consumer and industrial products.

“Polychem has manufactured strapping and cord products from recycled plastic since 1974,” he says. “But here are some little-known facts. We recycle more than 1 billion PET bottles a year, and we produce 40 million pounds of rPET [that is] used to create new bottles and containers for food, beverage, health and beauty and other products. We also reclaim and recycle hundreds of tons of waste each year that would have gone into landfills, or even worse, into oceans.

“Now, as Greenbridge, we’re bringing nearly 50 years of experience in recycling and sustainability to major companies that recognize the need for real change in their operations to meet circular economy and ESG goals and expectations,” Abuaita continues. “We can and are currently helping brands achieve measurable results.”

Greenbridge will continue to supply the North American market with a fully integrated portfolio of end-of-line packaging products, including polyester, polypropylene and steel strap and cord; tools, equipment and systems; and equipment repairs and services. It also will offer rPET and its new suite of sustainability services.

Hiring push

Lindsey Krauth, the corporate vice president of human resources at Greenbridge, says the company and its Evergreen division are expanding, which means the companies are hiring. “With the expansion and how quickly we’re growing, we are hiring on all fronts: IT, technicians and sales.” Despite the automation being employed at the Evergreen, she says 75 to 80 percent of the workforce is in production.

Latest from Recycling Today

- Reconomy Close the Gap campaign highlights need for circularity

- Nickel carbonate added to Aqua Metals’ portfolio

- EuRIC, FEAD say End-Of-Life Vehicle Regulation presents opportunity for recyclers

- Recyclers likely to feel effects of US-China trade war

- BCMRC 2025 session preview: Navigating battery recycling legislation and regulations

- Yanmar Compact Equipment North America appoints new president

- LYB publishes 2024 sustainability report

- Plum Creek Environmental acquires Custom Installation LLC