Photos: Matt Wittmeyer

It’s only been more than a month since COVID-19 started impacting U.S. businesses, but Sunnking Inc. is still finding new ways to revamp work flow each day. The company, based in Brockport, New York, works in information technology asset disposition (ITAD) and electronics recycling. When business closures started in late March, New York Gov. Andrew Cuomo deemed recycling an essential business, allowing Sunnking to continue working, though scaled back.

Over the last month, Vice President Adam Shine says the company has had to make some changes to accommodate the decrease in demand and the lack of incoming volume.

“We have had to furlough some of our staff,” Shine says. While volume is down, he says the furloughs were also done to decrease the amount of people in the facility at any given time.

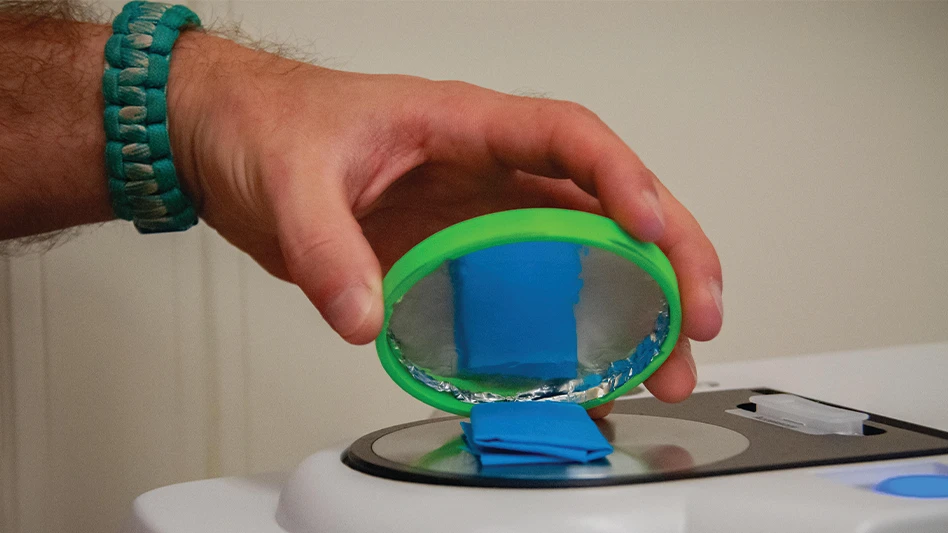

In addition to having fewer employees, recycling practices have changed a bit. Instead of sending items to be sorted right away, Shine says items are being held for a few days to ensure that if any of the coronavirus is present on the devices, it would be gone before anyone touches them.

Despite the decrease in incoming products, Shine says he’s hopeful for Sunnking’s business regardless. While fewer items are coming in, he says many more items are going out as more people work from home and are looking for lower cost, refurbished items to create their home offices.

While Sunnking is doing its best to focus on keeping business moving, the company also is making a conscious effort to help others. “I’ve told our sales department right now is not a time to call people to say ‘Hey, do you want to sell your electronics?’”

Instead of focusing on sales, Sunnking has given face masks to local hospitals, helped a Veteran’s Affairs hospital secure freight to transport beds, as well as sourced AC adapters for a Buffalo-area school district that transitioned to online learning.

When it comes to finances, Sunnking is waiting for its payroll protection loan. Shine says the company doesn’t have an exact plan in place on how all funds will be used, but he says it’s nice to have the extra help right now.

Going forward, Shine says many of Sunnking’s current employee safety protocols will remain in place for the foreseeable future. Employees will stagger their breaks and stay socially distant, and Sunnking also has ordered reusable, washable masks with the company logo, so employees don’t have to worry about disposable masks anymore.

When it comes to business interactions, Shine says he believes this pandemic will create a new normal for everyone. “I think this will cause a lot of people to reexamine their business when it comes to company meetings and face-to-face meetings.”

As businesses start to reopen, Sunnking is preparing for how to handle the potential increase in volume as people return to the office. If people bought items to create a home office, Shine says they may want to recoup some value and resell it. He says Sunnking has a resale website in the works for customers, so they can resell their items, without ever leaving their homes.

Sunnking was founded in 2000 and operates several facilities around New York, including a new facility to serve central New York and the capital region. It is New York’s first R2-RIOS (Responsible Recycling-Recycling Industry Operating Standard) certified electronics recycling, data destruction and ITAD management company dealing in end-of-life electronics management. It specializes in collecting, recycling and reselling electronics from companies, residents and municipalities.

Latest from Recycling Today

- APR launches Recycling Leadership Awards

- Private equity firm announces majority investment in Sprout

- Author predicts spike in silver’s value

- SWANA webinar focuses on Phoenix recycling collaboration

- Domestic aluminum demand up through Q3 2024

- IntelliShift honored at IoT Breakthrough Awards

- Ace Green Recycling finalizes plans for battery recycling site in India

- Ambercycle, Benma partner to scale circular polyester