DSM Engineering Materials

DSM Engineering Materials, Troy, Michigan, has announced that it has received an Innovation Award from the Society of Plastics Engineers (SPE) along with Ford Motor Co., Dearborn, Michigan, and Milwaukee-based Hellermann Tyton for the use of Akulon RePurposed recycled ocean plastic in the Ford Bronco Sport.

While recycled ocean plastics have been used to make items like clothing, shoes and other consumer products, Ford is the first automaker to use 100 percent recycled ocean plastic to produce car parts, according to the company.

“This is another example of Ford leading the charge on sustainability,” says Jim Buczkowski, vice president of research and Henry Ford technical fellow. “It is a strong example of circular economy, and while these clips are small, they are an important first step in our explorations to use recycled ocean plastics for additional parts in the future.”

Wiring harness clips are made from debris known as “ghost gear.” The parts are invisible to vehicle occupants, Ford says, weighing about 5 grams and fastening to the sides of the Bronco Sport second-row seats and guide wires that power side-curtain airbags.

Ford testing has shown that despite spending time in salt water and sunlight, the recycled ocean plastic material is as strong and durable as petroleum-based clips, and according to the company, the strength and durability of the nylon material equals that of previously used petroleum-based parts but with a 10 percent cost savings and less energy to produce.

“Solving the global challenge of ocean plastics will require our entire industry to step up and find innovative solutions to grow the circular economy,” says Lydia Swan, commercial director – Americas, DSM Engineering Materials. “We are very proud of the joint efforts of our team, Ford and HellermanTyton to make this innovative use of recycled ocean plastics possible, and we look forward to finding additional opportunities to reduce ocean plastic waste.”

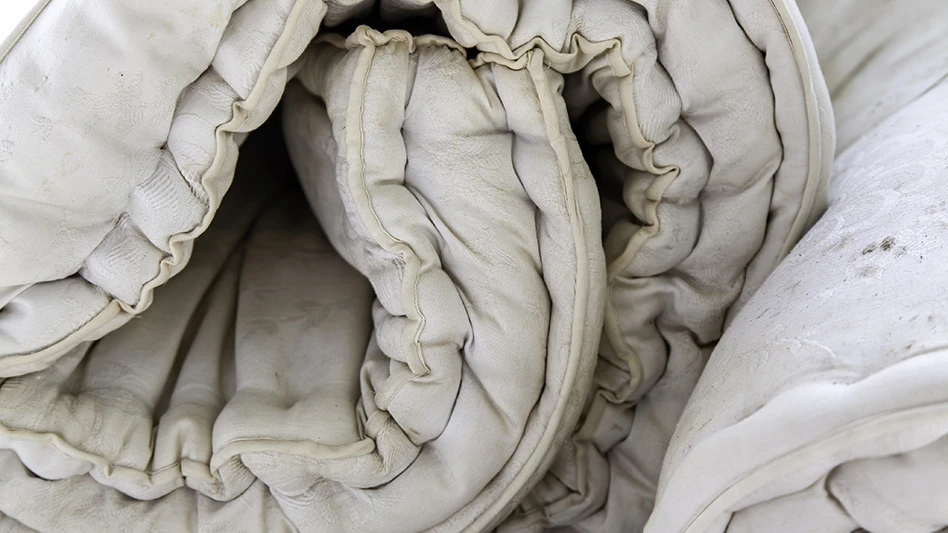

DSM’s Akulon RePurposed material is made using nylon fishing nets collected from the Indian Ocean and Arabian sea. The nets are washed of salt water, dried and extruded to form small pellets, which are injection-molded by HellermannTyton into the desired clip shape. The polyamide 6 (PA6) engineering material has performance comparable to new petroleum-based plastics, according to the companies.

In 2018, DSM launched the Akulon RePurposed PA6 to address the growing challenge of reducing plastic waste in the world’s oceans. According to the International Union for Conservation of Nature (IUCN), at least 14 million tons of plastic end up in the ocean every year, making up 80 percent of all marine debris. Much of the debris culminates in the Great Pacific Garbage Patch, which covers an area twice the size of Texas and three times the size of France, and the World Wildlife Federation estimates abandoned fishing nets account for as much as 46 percent of the waste in the Great Pacific Garbage Patch.

“As a global leader in cable management innovation, HellermannTyton strives for eco-friendly ways to pave the path for a more sustainable future,” says Anisia Peterman, automotive production manager at HellermannTyton. “Developments like this do not come easy, so we are proud to collaborate with Ford in support of a unique product solution that contributes to healthier oceans.”

Ford has a history of using recycled plastics not collected from oceans to produce various car parts. The company uses approximately 1.2 billion recycled plastic bottles per year—about 250 bottles per vehicle—and most recently used the bottles to produce lightweight, aerodynamic-enhancing, noise-reducing underbody shields on its 2020 Ford Escape.

The introduction of parts made from recycled ocean plastic builds on a global effort to help reduce debris that hampers sea life or clutters landfills, Ford says.Latest from Recycling Today

- Alpla calls 2024 year of recycling growth

- Altilium says agreement puts it on lithium recycling path

- NWRA, SWANA partner to address lithium-ion batteries

- Corinth, Texas, renews waste contract with CWD

- Fresh Perspective: Sarah Zwilsky

- Plastics Industry Association announces leadership changes

- QCC celebrates 50th anniversary

- Venture Metals acquires 2 nonferrous processors