Image provided by Danieli

Italy-based Danieli & C. Officine Meccaniche S.p.A. says it has received orders for eight of its Danieli Zerobucket electric arc furnaces (EAFs), adding the orders have been placed by five different Chinese steelmakers over the last six months.

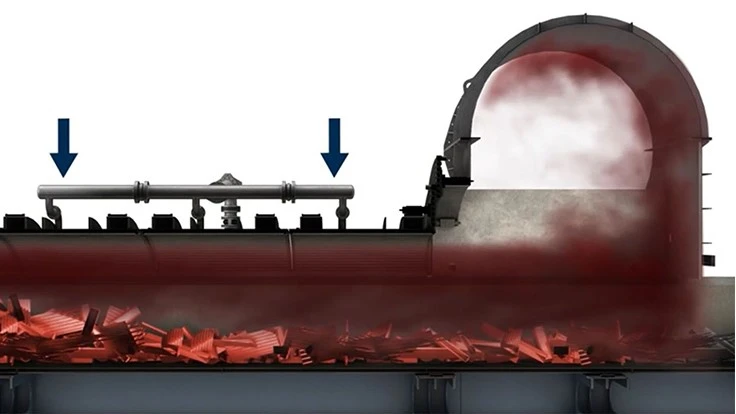

Danieli lists the Chinese-based steel producers as Qiananshi Jiujiang, Hebei Puyang, Tangshan Zhongshou, Changshu Longteng and Zhejiang Yuxin. Danieli says each of the firms “selected the original Danieli horizontal, continuous scrap-charge system, which ensures smooth, endless hot-scrap charging.”

As China ramped up its steel output in the previous four decades, it relied largely on blast furnace/basic oxygen furnace (BOF) technology. This has led steel producers in other nations to criticize the Chinese sector’s considerable carbon footprint.

Other industry analysts have looked at China’s growing ferrous scrap generation and predicted that if the nation did not start soon installing more EAF capacity, it could become a significant net exporter of ferrous scrap.

The Zerobucket technology purchased allows for a range of charge mixes, including hot metal, direct-reduced iron (DRI), hot briquetted iron (HBI) and scrap, according to Danieli. The furnace can work with up to 80 percent of hot metal charge, “replacing BOF converters and obtaining outstanding results in terms of short tap-to-tap time, boosting the overall steelmaking plant productivity,” the company says.

The ordered furnaces will have capacities from 210 to 330 tons per hour and are expected to start operating between the end of 2022 and the beginning of 2023.

Four of the EAFs were ordered by Tangshan, China-based Qiananshi Jiujiang, while the one ordered by Zhejiang Yuxin will be installed with what Danieli calls the first Tornado scrap conveyor system.

The Tornado, patented by Danieli, is described by the firm as a continuous scrap charge design that features a “variable-geometry preheating zone to automatically adjust and adapt the free cross-section, to create the optimal conditions for fume speed, temperature and process control.” The variable cross-section feature is designed to allow “the best pre-heating results with different scrap types available from the market, thus giving maximum purchase flexibility,” according to Danieli.

Latest from Recycling Today

- Lautenbach Recycling names business development manager

- Sebright Products partners with German waste management equipment company

- WasteExpo transitions to biennial format for enhanced experiences

- Study highlights progress, challenges in meeting PCR goals for packaging

- Washington legislature passes EPR bill

- PureCycle makes progress on use of PureFive resin in film trials

- New copper alloy achieves unprecedented high-temperature performance

- Gränges boosts profits and sales volume in Q1 2025