Shredding is more than just a way to downsize waste for disposal. It often is the first step in recycling or another material handling process. That’s the reason SSI Shredding Systems Inc. takes a hands-on approach to helping its customers secure the right solution for their applications.

“In the early years, our customers frequently came to us with unique problems. This compelled us to concentrate on engineering new solutions rather than off-the-shelf technology,” says Tom Garnier, SSI’s founder and president. “The idea that there was one solution for all just wouldn’t work,” he adds.

Customer First

“The customer relationship really has to come first,” says Dave Fleming, SSI director of sales and marketing. “With a mission statement that says, ‘To create and maintain loyal and satisfied customers,’ we’re highly focused on putting our customers’ success first.”

SSI offers a range of services as part of its sales consulting process. Material handling requirements and material analysis and testing begin the discussion. Output requirements and throughput capacities continue it, along with system design and consultation.

“We invest a lot of time upfront working with our customers to understand their current requirements and how those have developed, as well as trying to look to the future to understand how they see those evolving. That baseline ensures the solution we recommend is aligned with their requirements and goals,” says Fleming.

Working through business plans, cost analysis and ROI calculations also is part of the customer focus at SSI. “Helping our customers understand all of the elements and positioning them for success is part of the program for us,” he says. “We find that by taking that approach, we end up with long-term, highly satisfied customers. It’s part of the reason we have so many repeat customers.”

It Begins with Understanding

At SSI it’s all about understanding the application. “When we’re faced with an application we’ve never seen before, we’ll form an internal ‘think tank’ group to work on it,” says Lee Sage, SSI customer service manager. “Customer service, field service, engineering and sales all have a tremendous amount of application knowledge. These teams often have more than 70 years of collective experience in shredding and size reduction.”

Using their extensive application experience, these teams devise unique solutions for nearly every application.

“Getting to know our customers, their material and application and understanding what success means for them is foundational for us,” Fleming says. “Until we can understand what they need to accomplish, we’re not in a position to offer guidance on shredding solutions or system considerations.”

Sage adds, “We really want to go through an education process with our customers, so they understand how and why the solution works.”

“Material testing is often part of the process,” Fleming says. “Right now, we’re testing a lot of copper-bearing scrap. The market for those materials has changed, and so many processors are looking for methodologies to liberate and separate the material.”

Every piece of an SSI shredder, from the shafts and blades to the control systems and hydraulics, is built in-house. “This means that when we have to circle the wagons on a new application, we have skilled, experienced team members looking at every phase of the process and what it will require to deliver success,” Fleming says.

SSI also realized long ago that as important as its shredders are, integration into a system often was essential. As a result, its technicians and engineers developed a deep understanding of auxiliary equipment, infeed and discharge systems that allows SSI to provide turnkey systems and crucial engineering support when working with other system providers.

With highly experienced and dedicated application specialists, engineers, designers and technicians, often with 10 to 25 years of experience each, SSI is uniquely positioned to assist its clients.

Technology that Drives Results

Since 1980, SSI has designed proven industrial shredding solutions used in a wide variety of applications, including reduction, recycling, recovery and energy conversion. Its technology is built on the principles of low-speed and high-torque, with product lines spanning rotary shear shredders, rotary grinders and waste reducers.

“When it comes to low-speed shredding, we make every type of machine possible. This means we don’t have to try to sell what we have; we focus on getting the right machine for the customers’ application,” says Fleming.

Innovation is at the heart of the company. SSI holds patents on some of the industry’s most creative technology, which gives it the confidence to look any shredding problem in the eye to come up with a solution that integrates design benefits and provides increased efficiency and productivity.

A Winning Formula

“We’re so focused on getting customers the right shredder for their application and circumstance that we might help them acquire a used SSI that’s within their budget but is absolutely the right machine for them,” says Fleming.

“We’re willing to solve problems that other suppliers won’t even look at,” Sage says. “We’ve got a lot of highly experienced, smart people focused on customers and solutions.

“Listen, the first 10 shredders we built back in 1980 are still in service. If you put the right machine in the right application and properly maintain it, an SSI will run a long time,” he adds.

Its focus on customer success has made SSI Shredding Systems Inc. a worldwide leader in size reduction. Customers looking for a solution that’s tailored to an application and that will provide long-term production, efficiency and ROI need look no further than SSI.

What needs shredding?

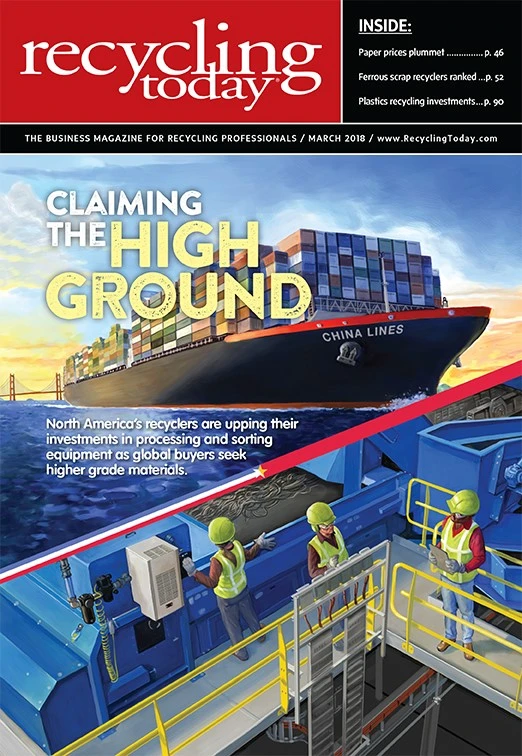

Explore the March 2018 Issue

Check out more from this issue and find your next story to read.

Latest from Recycling Today

- USTR announces phased measures designed to address China’s shipbuilding dominance

- APR, RecyClass release partnership progress report

- Clearpoint Recycling, Enviroo sign PET supply contract

- Invista expanding ISCC Plus certification program

- Redwood partnership targets recycling of medium-format batteries

- Enfinite forms Hazardous & Specialty Waste Management Council

- Combined DRS, EPR legislation introduced in Rhode Island

- Eureka Recycling starts up newly upgraded MRF