Conor Carlin got his start in the plastics industry working for Sencorp Inc., an original equipment manufacturer for thermoforming and packaging machinery. Carlin’s bachelor’s degree was in French, so Sencorp had asked him to manage its European business.

Carlin also has become involved with the Society of Plastics Engineers (SPE), Danbury, Connecticut. He currently serves as the society’s vice president of sustainability.

“The divisions encourage volunteerism, so I began to get involved as a thermoforming board member first,” he says. “From there, I co-chaired technical committees for the annual conference. In 2006, I took over as editor for the Thermoforming Quarterly magazine, a position I still hold today and enjoy greatly.”

Industry veteran and SPE leader Roger Kipp suggested Carlin join the SPE Foundation Board, where he served for two years before being elected to the executive board in 2017. “At the same time, I joined the Recycling Division as secretary and newsletter editor. This year, I was re-elected in a new position, that of VP, Sustainability,” he says.

Carlin shares more about his role at SPE and his thoughts about sustainability.

What does the SPE’s vice president of sustainability do? By creating this position at the board level, SPE will bring more focus and expertise to a topic that is, frankly, very wide-ranging. In the world of plastics, we have an opportunity to highlight and promote the work that our 20,000 members are doing on a daily basis.

What are some of the SPE’s initiatives in sustainability? We have two distinct groups dedicated to sustainability—Recycling and Bioplastics & Renewable Technologies—but many other groups also create content with sustainability themes.

What can individual engineers do about sustainability at their companies? From an individual perspective, all employees (not just engineers) can educate themselves about sustainability in their own companies. It takes time and effort to remain current on such a dynamic topic.

As editor of Thermoforming Quarterly, I have created a dedicated section for our readers so they can see how their peers are approaching sustainability. Stories range from solar incentives in California to zero-waste programs to M&A [mergers and acquisitions] in the European recycling sector.

Not every effort has to be a home run, but being aware of new developments in materials science or related technologies is a starting point.

Do you think this is a pivotal time for plastics recycling? This is a very thorny question. A cursory glance at LinkedIn these days suggests there is no shortage of controversy or strong opinions on this topic. It is a pivotal time—public pressure is coming to bear, and policymakers are making decisions now that will have impacts for many years to come. Like all difficult decisions, there will be unintended consequences.

I think it is fair to say that because plastics are so extremely efficient, they can be deemed the most environmentally friendly choice of material, yet the end-of-life management of plastics is imperfect, to say the least.

Different solutions are required in different geographic areas. Infrastructure plays a huge role; but, perhaps less visibly, so does a society’s priorities. If people are not willing to pay more for convenience, then it will be increasingly difficult to fund the correct infrastructure from a declining pool of funds.

With so much competing (and often inaccurate) information available, SPE serves as a repository for objective, science-based knowledge that can and should be shared more widely.

Are there any misperceptions about the plastics recycling or sustainability that you wish you could debunk?

Oof! Where do we start? I wrote a piece for LinkedIn recently about resin codes and misperceptions about what constitutes recyclability. Those who look at the entire ecosystem honestly will acknowledge that there are big challenges for plastics recycling, but a bigger challenge, in my opinion, is that we as a society are not willing to ask the hard questions and make the necessary sacrifices to enable true sustainability. Cost externalities are ignored or poorly understood by business and government. For example, there is heated debate about extended producer responsibility and who should pay for recycling programs, deposit schemes, takeback programs or infrastructure development, with some saying industry should pay and industry saying that governments (society, via taxes) should pay. Convenience has a cost: We all have to chip in.

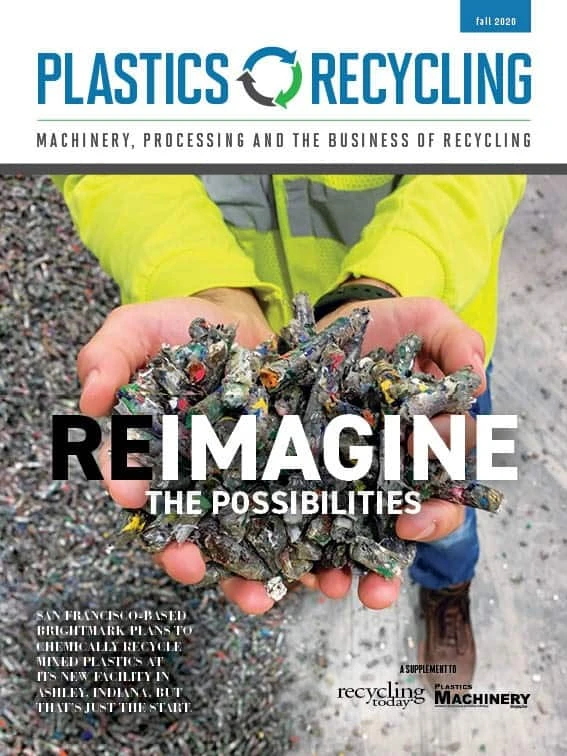

Explore the Fall 2020 Plastics Recycling Issue

Check out more from this issue and find your next story to read.

Latest from Recycling Today

- BMW Group, Encory launch 'direct recycling’ of batteries

- Loom Carbon, RTI International partner to scale textile recycling technology

- Goodwill Industries of West Michigan, American Glass Mosaics partner to divert glass from landfill

- CARI forms federal advocacy partnership

- Monthly packaging papers shipments down in November

- STEEL Act aims to enhance trade enforcement to prevent dumping of steel in the US

- San Francisco schools introduce compostable lunch trays

- Aduro graduates from Shell GameChanger program