Daisy, Apple's recycling robot, will disassemble iPhones returned to Best Buy in the U.S. and KPN in the Netherlands.

Apple, Cupertino, California, has announced plans to expand its recycling programs and to open a Material Recovery Lab in Austin, Texas, that will be dedicated to discovering future recycling processes. The new 9,000-square-foot facility will look for innovative solutions involving robotics and machine learning to improve on traditional methods like targeted disassembly, sorting and shredding. Apple reports that the lab will work with Apple engineering teams as well as academia to address and propose solutions to today’s industry recycling challenges.

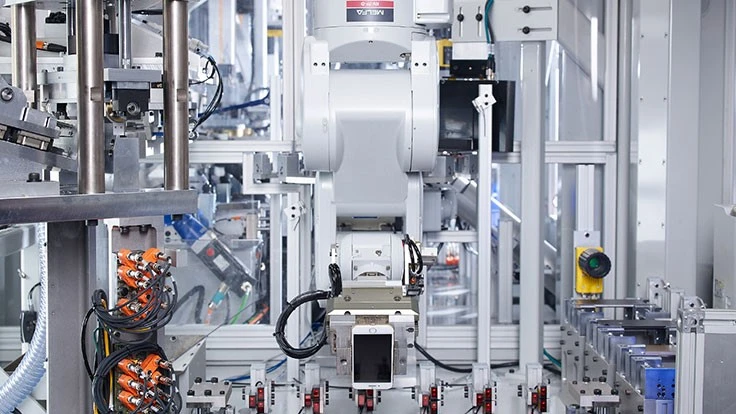

According to a news release from Apple, the company also plans to quadruple the number of locations U.S. customers can send their iPhones to be disassembled by Daisy, its recycling robot. Daisy will disassemble and recycle select used iPhones returned to Best Buy stores throughout the U.S. and KPN retailers in the Netherlands. Customers also can turn in their eligible devices to be recycled at any Apple store through apple.com as part of the Apple Trade-In program.

According to Apple, the company has received nearly 1 million devices through Apple programs and each Daisy can disassemble 1.2 million devices per year. In 2018, the company says it refurbished more than 7.8 million Apple devices and helped divert more than 48,000 metric tons of electronics from landfills.

Apple reports that Daisy is now able to disassemble 15 different iPhone models at the rate of 200 per hour. Once materials have been recovered from Daisy, they are recycled back into the manufacturing process. Apple sends iPhone batteries recovered by Daisy upstream in its supply chain. They are then combined with scrap from select manufacturing sites and, for the first time, cobalt recovered through this process is now being used to make brand-new Apple batteries.

“Advanced recycling must become an important part of the electronics supply chain, and Apple is pioneering a new path to help push our industry forward,” says Lisa Jackson, Apple’s vice president of environment, policy and social initiatives. “We work hard to design products that our customers can rely on for a long time. When it comes time to recycle them, we hope that the convenience and benefit of our programs will encourage everyone to bring in their old devices.”

In addition, Apple reports that it will be supporting the efforts of environmentally focused nonprofits, including Conservation International, SEE Foundation and The Recycling Partnership this year.

Latest from Recycling Today

- Aqua Metals secures $1.5M loan, reports operational strides

- AF&PA urges veto of NY bill

- Aluminum Association includes recycling among 2025 policy priorities

- AISI applauds waterways spending bill

- Lux Research questions hydrogen’s transportation role

- Sonoco selling thermoformed, flexible packaging business to Toppan for $1.8B

- ReMA offers Superfund informational reports

- Hyster-Yale commits to US production