As the recycling of construction and demolition (C&D) debris has become more prevalent throughout the United States, processors are learning that finding markets for the materials they produce is not always an easy task.

Once C&D is processed with grinders, screeners, magnets and picking stations, one realizes that the "fines" fraction can be a significant byproduct of the recycling process. Fines, which range from ¼-inch to 3-inch minus in size (depending upon each state’s reuse requirements and the processing line configuration), can comprise from 15 percent to 50 percent of the "processed" material stream.

So, what is in fines? The fines stream is typically a combination of sand/dirt, asphalt, brick, concrete, glass, gypsum, organics (e.g. wood, paper) and whatever else may come from a construction and demolition project site. Based on the fact that many construction and demolition projects use or produce a large variety of materials, the material tends not to be homogeneous in nature and can vary significantly based on geographical region.

END MARKETS. C&D fines have been utilized as an alternate daily cover (ADC) material at landfills since the 1980s. Fines are generated in the greatest quantities where disposal tip fees are higher, in places such as New England, New York, Florida and California, and are marketed for beneficial uses partially in an effort to reduce potential landfill disposal costs.

Currently, C&D fines are produced and utilized in almost any state where C&D processing occurs both in successful and not-so-successful applications. The predominant use so far, however, has been as landfill ADC.

Users of C&D fines have found that the material has positive properties and qualities if used correctly. Positive properties, which may be helpful in many applications, can consist of the following:

• Shedding water effectively based on the size and the material makeup,

• Resisting erosion and being capable of yielding a high angle of repose,

• Controling vectors and other nuisance conditions,

• Preventing fire if the organic content is low enough,

• Being easily spread, and

• Capable of providing for significant cost savings depending upon its application and the needs of the user.

Where can fines be used? The use of C&D fines typically depends on the processing line configuration, the amount of contamination within the material and state reuse regulations and policies. However, general applications include ADC, landfill closure activities, fill, landfill select layer, roadway stabilization and other potential uses where it could take the place of or be mixed with clean fill or other soil types.

Sound easy? It may be, but there are many considerations that C&D processors must take into account to reduce the potential for contamination, lessen liability and prove to regulators and potential users that the material will function as intended without creating "impacts."

UP CLOSE. For starters, recyclers should educate themselves on their material stream. Several questions should be asked when deciding what the potential end markets will be for this material, including:

What is the organic content of the material? The higher the organic content, the less likely the material will prevent fire or be good for structural uses. Typically, the screen size on your screening apparatus plays a part in the organic content. Smaller screens usually yield a lower organic content.

Does the C&D material you process have a lot of gypsum in it? High concentrations of calcium sulfate (the majority constituent mineral in drywall), under anaerobic conditions, can produce hydrogen sulfide gas. Hydrogen sulfide gas not only presents a nuisance odor (rotten eggs), but can also present considerable health threats if found in high concentrations. Gypsum in high percentages can also impact the structural properties of your material. You may consider instituting a gypsum removal program that encourages source separation or practice kick-sorting prior to consolidation and processing. Also, a smaller screen size may help reduce gypsum content. A processor should remember that it is the final use that will dictate whether the amount of gypsum could present a problem.

Will the material contain contaminants such as copper, chromium or arsenic? If pressure-treated wood is in the C&D you process, there’s a good chance that it contains chromated-copper-arsenate-treated (CCA) wood, which can make the fines have total concentrations of constituent chemicals (arsenic, chromium) above applicable state reuse standards, even though they may not leach in concentrations that are greater than Federal Land Ban standards. These materials should be identified so that they don’t present a human exposure risk. However, depending upon the use of the material, it may not matter whether it contains CCA wood or not.

Do the fines contain lead? Lead is an issue that pertains to the age of the C&D you process. The older the buildings are in the geographical area, the more likely incoming materials contain lead. Also, areas being redeveloped will produce less new construction materials and more demolition materials for recycling. So, the chance that fines will contain lead is higher. Lead in fines is usually associated with lead paints. However, other materials that contain elemental lead, such as roof flashing, window weights, water service lines and solder, also can contribute this issue.

Total lead concentrations in fines can vary from virtually none to levels in the thousands of parts per million. Based on the variability in the region, lead can potentially restrict the potential end uses of the generated fines and eliminate their use in areas with high risk of exposure, such as residential applications. Lead issues may force a consideration of dirty vs. clean wood "batch" processing or wood removal programs prior to screening.

| Call for Fines Data |

|

The CMRA Issues & Education Fund is developing a database of all available test results on C&D fines from across the country. The goal is to provide recyclers, regulators and other interested parties with true empirical, scientific data on what is actually in fines, according to William Turley, executive director of the CMRA (Construction Materials Recycling Association). While these materials do differ from region to region, the intention of the study is to provide information to help determine what can be expected to be produced in the fines stream of C&D recycling facilities, and also help ascertain which end markets such fines can be used for. Green Seal Environmental, Sandwich, Mass., will gather and organize the results. Anyone with fines data who wants to add their information to the study should contact Greg Wirsen at Green Seal, (508) 888-6034 or greg@gseenv.com. |

Since the fines material is waste-derived is it okay for it to look like a waste? Processors have to remember that they are processing and recycling C&D to make products and money (one certainly hopes). Therefore, the performance and visual characteristics of the fines produced go a long way in a company’s marketing efforts. If the materials are not aesthetically pleasing, contain bits of insulation, paper or plastic that can become airborne or has the potential to create a nuisance condition, such as dust, then the value of the fines product can be reduced to a great extent.

MEETING THE MARKET. In conclusion, it is imperative that processors understand the chemical and physical characteristics of their fines material so that viable markets can be sought within the geographical area in which they operate.

Remember to design the process around market needs rather than to seek outlets based on the process. Considering today’s recycling markets and economics, the profit margins may not be significant in your area.

Having sound economical outlets for C&D fines as well as the other materials produced could mean the difference between a successful and a failing recycling endeavor.

C&D fines certainly have their potential uses and can provide value and savings to end users, as long processors are educated regarding the products generated and cater the recycling process toward the product’s final use. Also, processors must look at their fines material from an industry-wide perspective. Learn from your colleagues and share the important information that you have gained from studying this material in the past.

Rogue users of this material have the ability to spoil many benefits that can come from utilizing C&D derived materials. Therefore, education and information sharing is imperative so that the growing fines market will be sustained for many years to come. Without this, mixed C&D processing will not realize all of the benefits that it can achieve.

The author is a principal of Green Seal Environmental, Sandwich, Mass., and regional director of the New England Chapter of the Construction Materials Recycling Association. He can be contacted via e-mail at greg@gseenv.com.

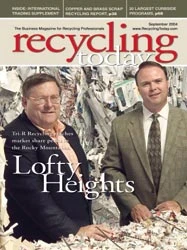

Explore the September 2004 Issue

Check out more from this issue and find your next story to read.

Latest from Recycling Today

- Lego creates miniature tire recycling market

- Lux Research webinar examines chemical recycling timetables

- Plastics producer tracks pulse of wire recycling market

- Republic Services, Blue Polymers open Indianapolis recycling complex

- Altilium produces EV battery cells using recycled materials

- Brightmark enters subsidiaries of Indiana recycling facility into Chapter 11

- Freepoint Eco-Systems receives $50M loan for plastics recycling facility

- PET thermoform recycling the focus of new NAPCOR white paper