Mischaracterizations in Europe of ferrous and nonferrous scrap as waste are poised to cause considerable challenges to the scrap recycling sector in the 27 nations of the European Union. The dialogue surrounding a proposed policy change also brings to the forefront how thoroughly recyclable metals are.

In the U.S., the Washington-based Institute of Scrap Recycling Industries (ISRI) long ago began a campaign with the message “scrap is not waste.” ISRI, likewise, has long urged its member companies to stay in touch with elected officials so that same message is carried to policymakers.

For whatever reason, the word “waste” still is attached too frequently to commonly recycled materials in Europe (including the ubiquitous use of the term “waste paper” for highly recyclable cardboard).

While “waste copper” or “waste steel” are not terms often found in English-language European news coverage or documents, the unfortunate reality for recyclers across the Atlantic is that any material collected as a discard in the EU too often is regulated as waste.

Europe-based trade groups have been trying to change that circumstance, and part of that effort involves emphasizing the high metals recycling rate, whether they are melted within the EU or beyond.

“The circularity of metal is a proven asset for the sector and a major factor in aluminum can makers’ effort to regain market share.”

The circularity of metal is a proven advantage for the sector and a major factor in aluminum can makers’ effort to regain market share. In the U.S., the widespread adoption of scrap-fed electric arc furnace (EAF) steel technology boosts not only its circularity credentials but also offers the U.S. a smaller average carbon footprint compared with the rest of the world.

In the effort to reduce greenhouse gas (GHG) emissions, alternative (nonfossil fuel) energy and electric vehicles have received the most attention. Some climate watchers have become dismissive or even hostile toward recycling, preferring a “get by with less” message.

That latter attitude is unlikely to stop metals companies from playing up the material’s circularity success story. Even those taking individual action to reduce GHG emissions must make choices in packaging or transportation. Thus, reminders that metal is highly recyclable can be worthwhile.

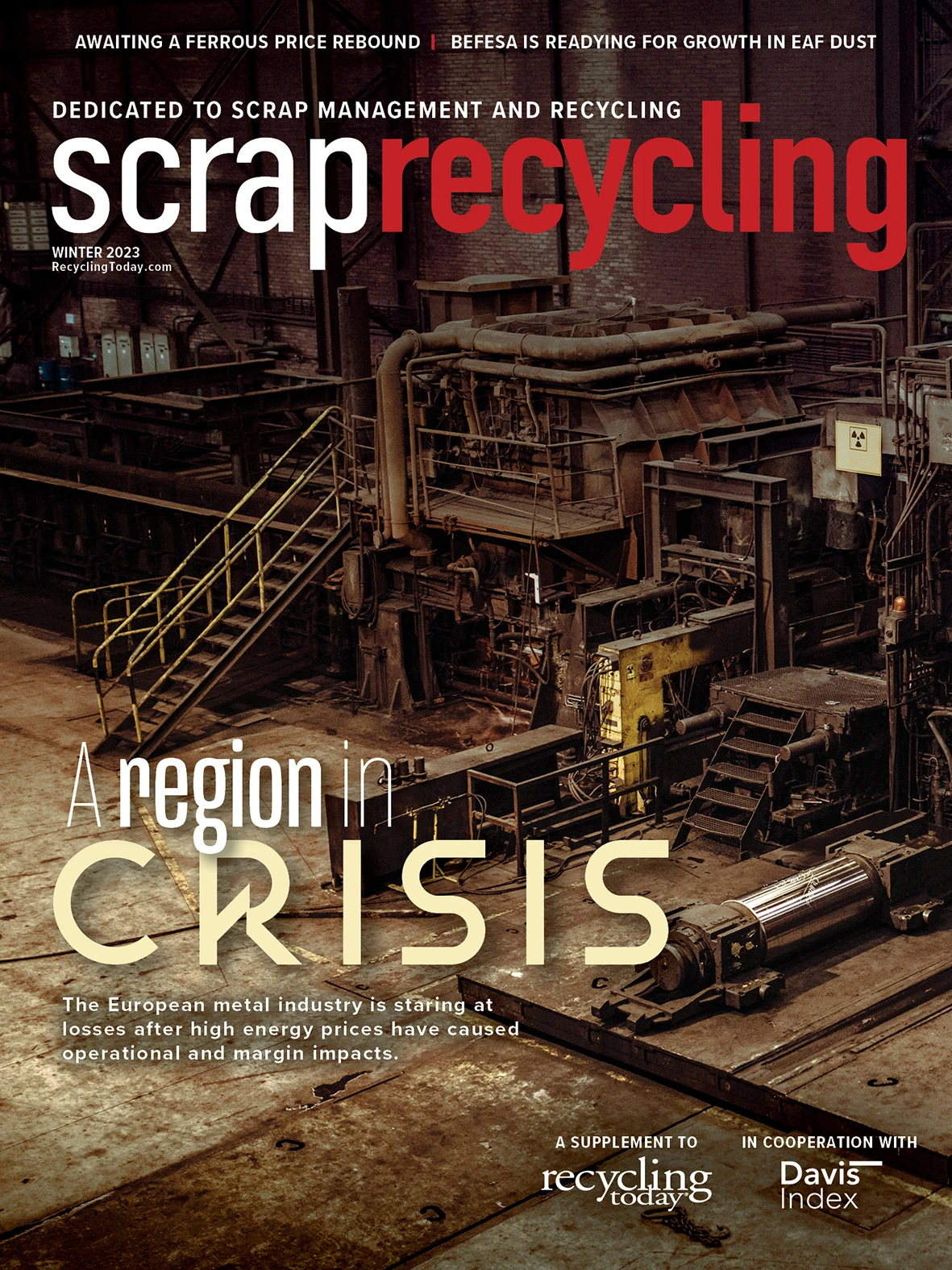

Images of sprawling mill complexes with smokestacks and piles of coal could continue to be what older Americans envision when they hear “steel industry.” The warehouse-like appearance of a minimill has not yet become similarly ingrained.

Those minimills, however, have created a recycling powerhouse. A 2021 report prepared by two U.S. steel industry trade groups found that, using a 10-year rolling average, “The overall U.S. [steel recycling] rate ranges between 71 percent and 75 percent since 2012.” It will be up to metals producers and trade associations to keep broadcasting that message.

Explore the Winter 2023 Scrap Recycling Issue

Check out more from this issue and find your next story to read.

Latest from Recycling Today

- Athens Services terminates contract with San Marino, California

- Partners develop specialty response vehicles for LIB fires

- Sonoco cites OCC shortage for price hike in Europe

- British Steel mill’s future up in the air

- Tomra applies GAINnext AI technology to upgrade wrought aluminum scrap

- Redwood Materials partners with Isuzu Commercial Truck

- The push for more supply

- ReMA PSI Chapter adds 7 members