Incentivizing sorters. Manual sorting is the first and last line of defense in a MRF. Sorters remove objects that cause jams and downtime and remove prohibitives from final product streams. Setting targets and providing incentives to sorters can stimulate productivity, increase uptime and improve product quality. They win when you win.

2. How can MRFs im- prove fiber quality?Nonwrapping screens create cleaner fiber streams and are being used to target larger grades of paper, while optical sorters are now being installed to target smaller fiber using a positive sort to achieve the highest quality.

3. How can MRFs best deal with the rising percentage of film and decreasing percentage of fiber?The quantity of newspaper in the stream still requires the use of traditional screening; however, the use of optical sorters to target the smaller fractions of fiber, including small OCC (old corrugated containers), is becoming increasingly popular. Positive removal of fiber from the system leaves the film in the negative fraction, which can be cleaned up using ballistic separators.

Ballistics are currently utilized for the final cleanup of the container stream to remove any remaining 2D items and small fines. The limited capacity of these machines inhibits them from completely replacing disc screening, but as the percentage of large fiber continues to drop, ballistics (in conjunction with optical sorting) will gain a stronger presence in single stream MRFs.

5. How should recyclers consider using robots?Robot technology never caught on in Europe after a decade of R&D, so why would it make a significant impact in the U.S.? Currently, robots are not being developed for presort, fiber QC or container separation. Their role is limited to plastic container QC. My suggestion: invest in quality optical sorting. Why do 60 ppm (picks per minute) with a robot when you can do 600 ppm with an optical sorter?

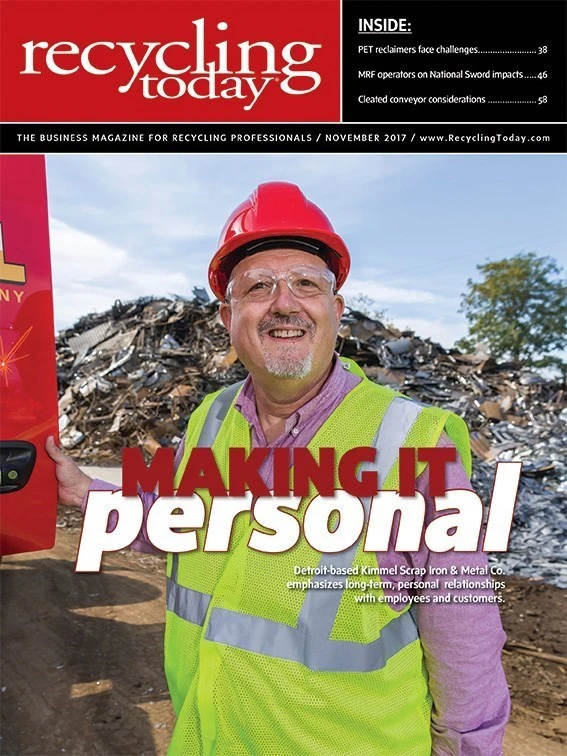

Explore the November 2017 Issue

Check out more from this issue and find your next story to read.

Latest from Recycling Today

- Phoenix Technologies closes Ohio rPET facility

- EPA selects 2 governments in Pennsylvania to receive recycling, waste grants

- NWRA Florida Chapter announces 2025 Legislative Champion Awards

- Goldman Sachs Research: Copper prices to decline in 2026

- Tomra opens London RVM showroom

- Ball Corp. makes European investment

- Harbor Logistics adds business development executive

- Emerald Packaging replaces more than 1M pounds of virgin plastic