We have seen increasing momentum and demand for primary shredders in North America for waste-to-energy, composting, wood waste, natural disaster cleanup and construction and demolition applications. The general need for volume reduction of materials previously thought to be too tough or bulky for existing technology also has increased.

With mobile primary shredders, you have the ability to bring the reduction equipment to the waste stream, which typically reduces transportation costs by as much as 10:1. Shredding these bulky materials on-site also greatly reduces material handling costs.

2. How can primary shredders benefit companies with multiple material shredding needs?

The Haas Tyron transportable shredder has the ability to process materials ranging from green waste to baled aluminum extrusions to mixed streams, such as construction debris, and more. By simply adjusting the settings on the machine, we can vary shred size, throughput and even capability in terms of capturing and shredding difficult material.

Sites such as transfer stations can benefit immensely from using this machine for batch processing. You can shred wood one moment, then move on to white goods, mattresses and more.

3. What advantages can transportable hydraulic shredders offer in terms of durability and output?

The Haas Tyron has been designed to operate 24/7 in all weather conditions, ranging from extreme heat to frigid climates. The machines are equipped with proven Scania industrial engines, top-of-the-line closed loop hydraulic systems and an easy-to-use operator interface.

Throughput rates can be optimized and even controlled by simple program changes to match downstream equipment requirements.

4. What features should waste processors look for when buying a primary shredder?

Choosing a shredder with an independent shaft control will provide you with the most versatility when processing varying material streams. The Haas Tyron shredders have the ability to run either shaft in forward or reverse, together or separately, and at different rpm for varying lengths of time. The main advantage of this feature is that tough materials can be broken down with a random shredding action (always reorienting material in the cutting chamber) so that soft pliable materials, such as plastics and wire, will not wrap the shafts due to the varying rpm and back-and-forth shaft motion.

5. What are the maintenance considerations for owners of these shredders?Ideally, they will have chosen a shredder with cutting tools that can be maintained and rebuilt on-site. The Haas Tyron’s cutting chamber is a unique design of welded, hard faced tools, combs and breaker bars that can be easily touched up or repaired back to the original state when worn. With regular maintenance, these chambers will last for years, maintaining the original reduction performance. There are no replaceable tips to break off, wear or seize in their holders and no chamber screens to wear or jam. Shredders without internal chamber screens typically have the highest throughputs with the least chance of damage from materials that cannot be shredded.

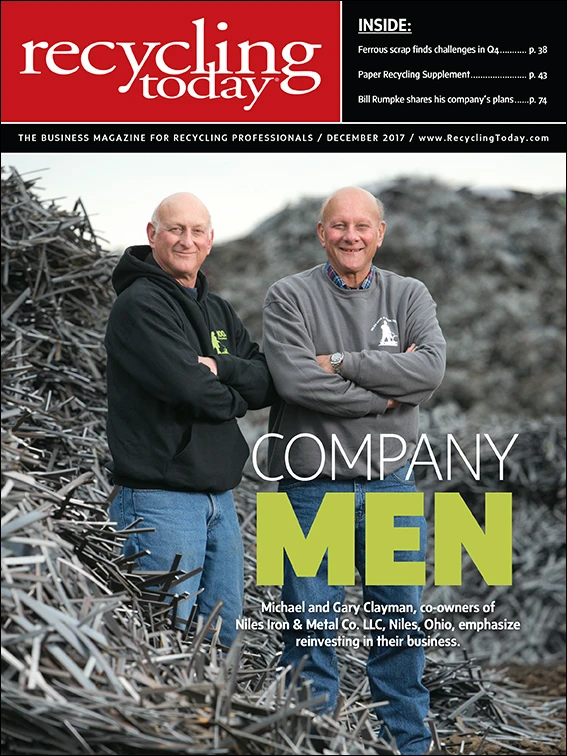

Explore the December 2017 Issue

Check out more from this issue and find your next story to read.

Latest from Recycling Today

- Phoenix Technologies closes Ohio rPET facility

- EPA selects 2 governments in Pennsylvania to receive recycling, waste grants

- NWRA Florida Chapter announces 2025 Legislative Champion Awards

- Goldman Sachs Research: Copper prices to decline in 2026

- Tomra opens London RVM showroom

- Ball Corp. makes European investment

- Harbor Logistics adds business development executive

- Emerald Packaging replaces more than 1M pounds of virgin plastic