1. How do I determine the right shredder for my business application?

Shred-Tech

Industrial Sales Engineer

First, it’s essential to determine the required shred size, which dictates the appropriate shredder type. In recycling applications, the processor you intend to sell your shredded scrap to may influence the preferred sizes. Coarse shredding is sufficient for volume-reduction purposes, while confidential product destruction can be tailored to meet specific DIN specifications—the European security standard for destruction developed by the German Institute for Standardization. Once the shred size and shredder type are chosen, the necessary throughput capacity will determine the size of the shredder and the physical size of the product being shredded also will influence the cutting chamber size.

2. What’s the difference between single-, dual- and four-shaft shredders?

The single-shaft shredder employs a medium-speed rotor against a stationary bed knife and a screen for consistent shred size. Material is fed through a hydraulic ram to the rotor. In contrast, the dual-shaft shredder features two low-speed, counter-rotating shafts of knives that shear material into strips, with cleaning fingers to remove material from between knives. Material is gravity-fed from above. Meanwhile, four-shaft shredders have two upper and two lower counter-rotating shafts of knives to shear and feed material, lacking cleaning fingers but also utilizing a screen for consistent shred size and are gravity-fed as well.

3. How do you customize a shredder for different shred sizes and throughputs?

Both dual- and four-shaft shredders offer adjustable knife width and the option to increase the number of hooks on the knives to achieve the desired shred size and enhance throughput. Additionally, these shredders come with various drive options that can be chosen based on the required throughput capacity.

4. What kind of maintenance is required for a shredder and what is the warranty like?

To maintain the shredder’s optimal performance, regular maintenance involves weekly greasing of bearings and inspecting oil level, knife tightness and wear and bolt tightness. The recommended oil change schedule would be a change after the first three months and, subsequently, every six months. Additionally, the standard warranty offered by Shred-Tech covers 12 months from the date of shipment or 2,000 operating hours, whichever comes first, and extended warranty options can be provided upon request.

5. If I can’t perform the maintenance myself, is there service support available?

Absolutely. Shred-Tech maintains service centers in both the U.S. and Canada and has skilled service technicians stationed at various strategic locations across North America, facilitating efficient and responsive support for their customers.

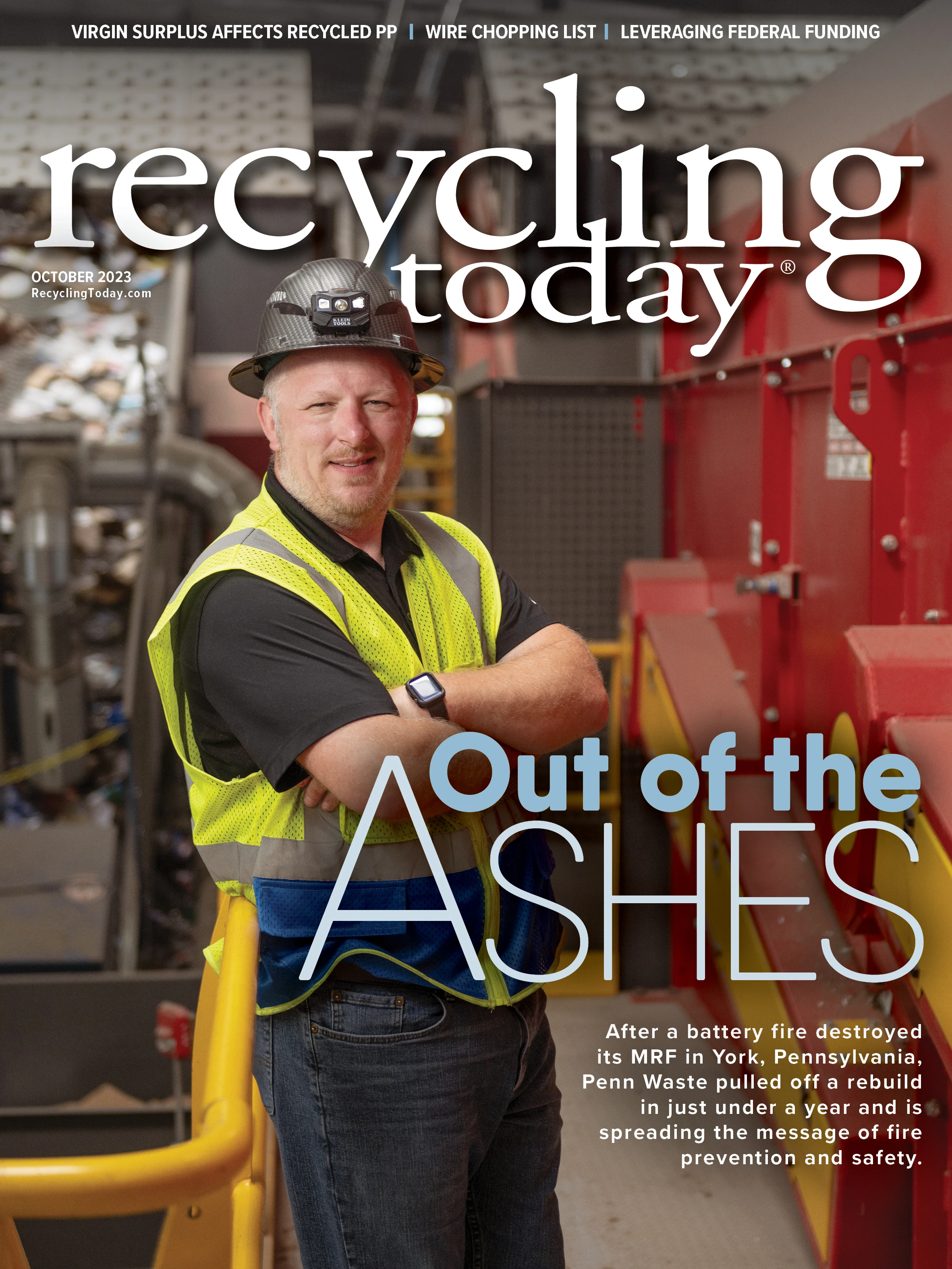

Explore the October 2023 Issue

Check out more from this issue and find your next story to read.

Latest from Recycling Today

- Joe Ursuy elected to NWRA Hall of Fame

- RRS adds to ownership team

- S3 Recycling Solutions acquires Electronics Recycling Solutions

- Nextek, Coveris to recycle food-grade plastic film

- Recyclekaro expands recycling capacity

- USTR hears comments on port fee proposal

- C&D World 2025 hits record attendance and exhibitor numbers

- Denali now offers mobile depackaging service