When Recycling Today last published its list of North America’s largest ferrous scrap processors, the figures reflected 2015’s volume. Much of that year scale prices were in a trough, and scrap collectors or peddlers had little motivation to seek out obsolete scrap.

Our updated list is based on processing volume figures for 2017, a year when improved scale pricing increased peddler activity and caused auto dismantlers to direct their auto hulks to

At the same time, the construction sector and the automotive industry each enjoyed a relatively healthy year in 2017, which provided more sources of ferrous scrap for recyclers competing to keep material flowing into their yards.

Also factoring into higher volume figures is the steady march of merger and acquisition (M&A) activity in 2016 and 2017. That phenomenon caused some company names from previous lists to disappear but also contributed to higher volume figures for other firms.

Following the footprints

Nearly all of the large scrap companies reporting 2017 figures to Recycling Today have shown volume increases compared with 2015, with some gaining 25 percent or more in volume.

Although

Many of those Midwest-based processors, however, have operations in the Southeast or farther west. Cincinnati-based David J. Joseph Co. (DJJ), for instance, has many facilities in Florida and Texas; Detroit-based Ferrous Processing & Trading (FPT) has yards in Florida

In 2017, a year of multiple hurricanes in the Southeast and Texas, having locations in those regions almost certainly played a role in the double-digit volume increases for scrap yard operators whose processing work tied into major cleanup efforts.

North America’s largest ferrous scrap companies also are growing by acquisition, with only a few new “greenfield” sites having been opened in the previous 24 months.

Among the largest acquisitions in the previous two years was the purchase of Illinois-based Behr Iron & Metal by St. Louis-based Alter Trading Corp. In the previous edition of this list, Alter had ranked as the eighth largest processor, while Behr Iron & Metal placed at No. 18.

Also on the acquisition trail has been Orange, California-based SA Recycling. That company, which placed 11th on the March 2016 list, has subsequently acquired the former 20th-ranked company, Newell Recycling of Atlanta.

SA Recycling also added yards and volume—and continued to deepen its footprint in the Southeast—with its 2017 purchase of Alabama-based Tennessee Valley Recycling from the Denbo family.

Other “wider footprint” moves in the previous two years have included New York-based Upstate Shredding’s investments in Pennsylvania and the ongoing re-emergence of the Rifkin family in the Midwest scrap sector. Danny Rifkin-led MetalX, which is based in Indiana and not yet among the 20 largest ferrous scrap processors, is building a sizable auto shredding greenfield facility in northwest Ohio.

Another set of executive-level decisions large scrap processing companies are making involves whether to remain involved in sectors related to ferrous scrap processing, including auto dismantling and steelmaking.

Upstream and downstream

Throughout the previous several decades, operators of electric arc furnace (EAF) steelmaking companies have been among those also investing to buy and process ferrous scrap.

The steelmaking activities of Texas-based Commercial Metals Co. (CMC) date back to the 1940s, with Oregon-based Schnitzer Steel Industries being another firm that has long produced steel and operated scrap yards.

In the 21st century, two of America’s largest EAF steelmakers got more deeply involved with the ferrous scrap industry via acquisition, when Nucor Corp. purchased DJJ and Steel Dynamics Inc. purchased OmniSource Corp.

At the start of 2018, CMC acquired steel mill assets from Brazil-based Gerdau that may ultimately affect the ferrous scrap processing strategies of both firms.

CMC’s purchase of four EAF mills with a combined output of 2.5 million tons of steel also included downstream rebar fabrication plants. The announcement of the transaction did not mention scrap yards, but the sale of the mills in California, Florida, New Jersey and Tennessee could spur CMC to increase its scrap processing presence in those regions.

At the same time, with less melt shop capacity to supply, it becomes unclear whether Gerdau will maintain its presence as a processor of some 3 million tons of scrap material in the U.S. (One month after the sale of mills to CMC, Gerdau also announced the sale of a wire rod mill in Texas to a group of Florida-based investors.)

Just as steelmakers invest

Several of the companies represented on the Largest Ferrous Scrap Processors List operate auto dismantling yards, often with a “self-serve” model that allows individuals to come harvest needed components, leaving the rest to be scrapped.

Schnitzer Steel Industries has built one of the more extensive auto dismantling networks. Its Pick-n-Pull subsidiary now has 53 self-service auto recycling facilities found in 15 different states and two Canadian provinces.

On its website, Schnitzer Steel indicates Pick-n-Pull purchases “approximately 350,000 used and salvaged vehicles annually from tow companies, private parties, auto auctions, city contracts and charitable organizations.”

In its 2017 fiscal year, Schnitzer Steel recorded $125 million in

As Schnitzer has built up its Pick-n-Pull network, other large ferrous processors have followed suit to different extents.

Soave Enterprises, the private company that owns Detroit-based FPT, has created a companion company called Parts Galore that operates three self-serve auto parts harvesting yards in or near Detroit. DJJ’s U-Pull-&-Pay subsidiary has 11 locations as far east as Pittsburgh and as far west as Phoenix, and Alter Trading is experimenting with its Wrench-N-Go concept with one location each in Iowa and Wisconsin.

With scrap volumes

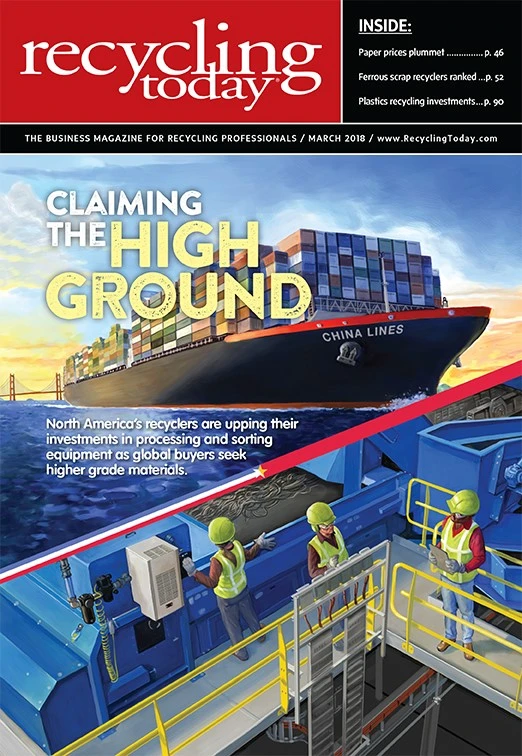

Explore the March 2018 Issue

Check out more from this issue and find your next story to read.

Latest from Recycling Today

- APR, RecyClass release partnership progress report

- Clearpoint Recycling, Enviroo sign PET supply contract

- Invista expanding ISCC Plus certification program

- Redwood partnership targets recycling of medium-format batteries

- Enfinite forms Hazardous & Specialty Waste Management Council

- Combined DRS, EPR legislation introduced in Rhode Island

- Eureka Recycling starts up newly upgraded MRF

- Reconomy Close the Gap campaign highlights need for circularity