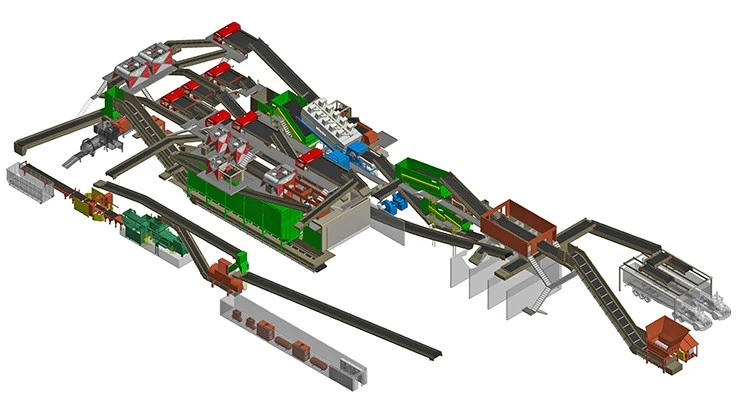

RePower South (RPS), North Charleston, South Carolina, has begun construction of the Berkeley County Recycling and Recovery Facility to process mixed waste. The turnkey system will be provided by Bulk Handling Systems (BHS), Eugene, Oregon, under an engineering procurement and construction (EPC) agreement with Barnhill Contracting Co., Rocky Mount, North Carolina.

When production begins in early 2019, the Moncks Corner, South Carolina, plant will process 50 tons pe hour of mixed waste sourced from Berkeley County, recovering recyclable commodities and a fuel feedstock. The plant includes optical sorters from National Recovery Technologies (NRT), Nashville, Tennessee, and BHS’ Max-A Autonomous Quality Controls (AQCs).

RPS says it partners with communities to maximize recycling recovery and landfill diversion at the lowest overall cost.

China’s National Sword policy has left many communities contemplating how to best manage recycling, with some areas in the U.S. currently landfilling papers, plastics and commodities that had previously been recycled. The RPS facility is designed to recover all recyclables rather than only those placed in a recycling bin.

Beyond recycling, the facility is designed to recover nonrecyclable papers and plastics for production of ReEngineered Feedstock, a renewable fuel sold to industry, cement and utility customers to replace coal in production processes.

“This system allows us to cost-effectively increase a community’s recycling as well as produce a low-carbon, clean fuel from waste that is typically landfilled,” RPS President Bob Shepard says. “BHS systems are a critical component of our ability to offer a better, more cost-effective solution to manage a community’s waste disposal. We are very excited to bring this solution to the citizens of Berkeley County, South Carolina, and are grateful to the leadership of Berkeley County for selecting RPS and systems partners, BHS and Loesche Energy Systems.”

The BHS FiberPure system, consisting of BHS screens, NRT optical sorters and Max-AI AQCs, is designed to remove contaminants to produce a clean end product without the need for manual sorters. The nonrecyclable fibers and plastics destined for fuel are sent through NRT SpydIR optical sorters equipped with MetalDirector options to remove unwanted contaminants. Max-AI AQCs are also used in each sorting position on the container line. In total, the system contains seven NRT optical sorters and nine Max-AI AQCs.

“With NRT optical and Max-AI technology, we have an almost unlimited degree of flexibility to create a wide variety of high-quality products to serve multiple markets,” Shepard says. “The technology will maximize the recovery and quality of those products and with Max-AI technology, there’s no real need to expose people to this work during the QC [quality control] process.”

In conjunction with BHS and RPS’ fuel system partner, Loesche Energy Systems, located near London, the fuel system contains a Loesche RocketMill for size reduction and two PAAL balers from Kadant, Westford, Massachusetts. A PAAL Konti 500 bales all commodities headed to the secondary market, including ferrous, aluminum, cardboard, paper and plastics and fuel is baled by a PAAL Dokon 500.

“RePower South is showing that it is possible today to help communities increase recycling with the existing waste stream while also providing the flexibility to adjust to any market condition or opportunity,” BHS CEO Steve Miller says. “The system is built to run with low operating costs over multiple shifts and has the ability to adjust its outputs to meet market conditions. The waste stream in Berkeley County is a resource which can be fully managed, and BHS is excited to help make it happen.”

Latest from Recycling Today

- APR, RecyClass release partnership progress report

- Clearpoint Recycling, Enviroo sign PET supply contract

- Invista expanding ISCC Plus certification program

- Redwood partnership targets recycling of medium-format batteries

- Enfinite forms Hazardous & Specialty Waste Management Council

- Combined DRS, EPR legislation introduced in Rhode Island

- Eureka Recycling starts up newly upgraded MRF

- Reconomy Close the Gap campaign highlights need for circularity